High-Speed Packaging Molding for Diverse Applications

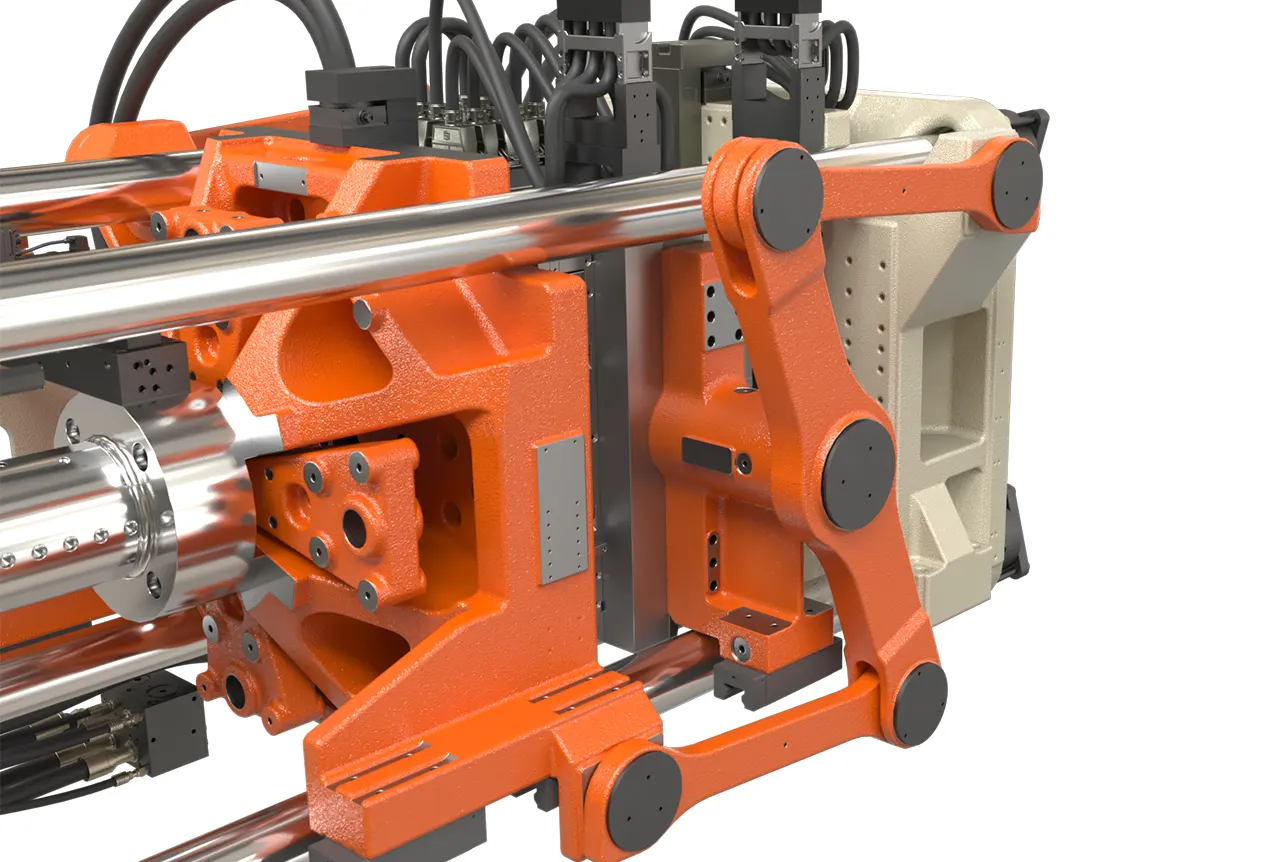

HyLECTRIC® continues Husky's commitment to packaging excellence, delivering superior performance across multiple applications:

- Thinwall packaging: Aggressive cycle times with consistent wall thickness and high part quality

- Industrial pails: High-throughput melt delivery for demanding applications

- Specialty closures: Wide tie-bar spacing for high-cavity mold configurations

- Medical devices: Process repeatability meeting stringent regulatory requirements

- Cosmetic, cutlery and other consumer packaging: Material flexibility across diverse applications