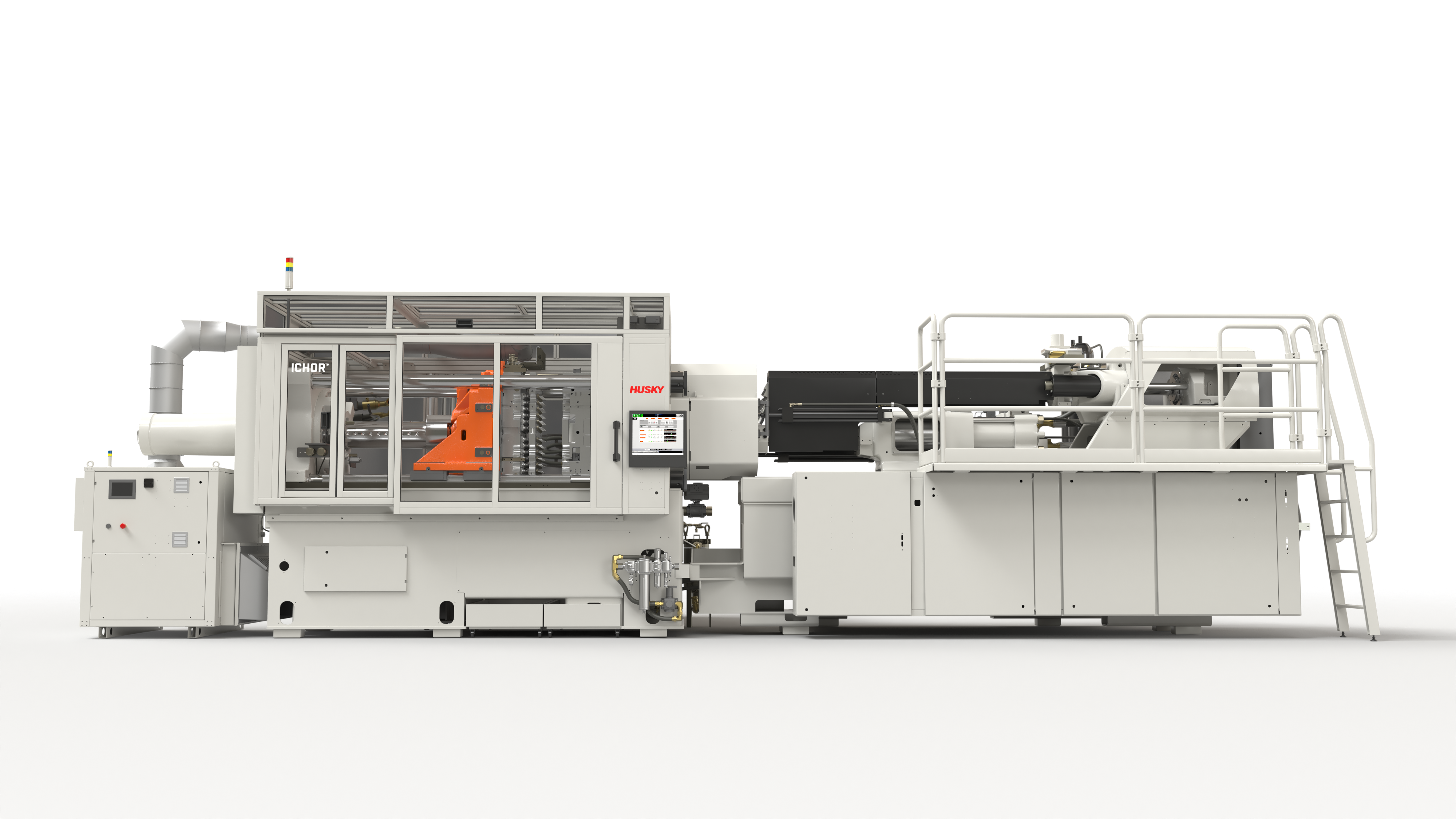

High Output PET Injection Molding Systems

The Husky HyPET®6e platform, enhanced with our High Performance Package (HPP) technology, sets new standards in sustainable molding with unprecedented machine, mold, and auxiliary integration to deliver:

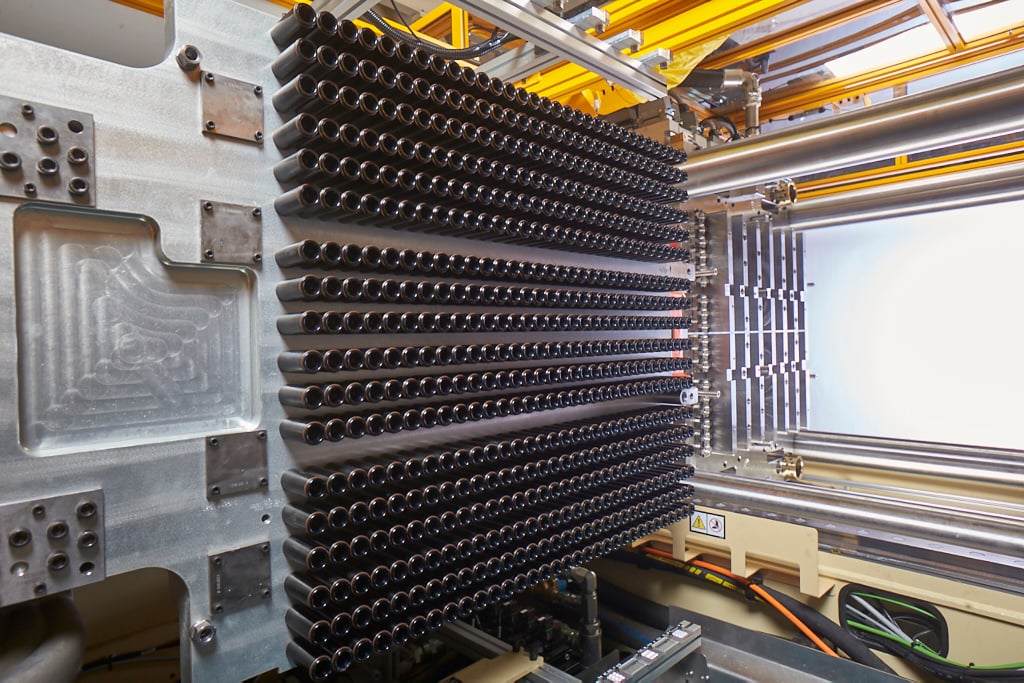

- Superior rPET processing with up to 100% recycled content capability

- 35% reduced energy consumption compared to previous generations

- Integrated systems approach with seamless component communication

- Intelligent Mold ID technology ensuring optimal compatibility

- Optimized cycle times and part quality through precise control systems

- Advanced sustainability features supporting circular economy goals