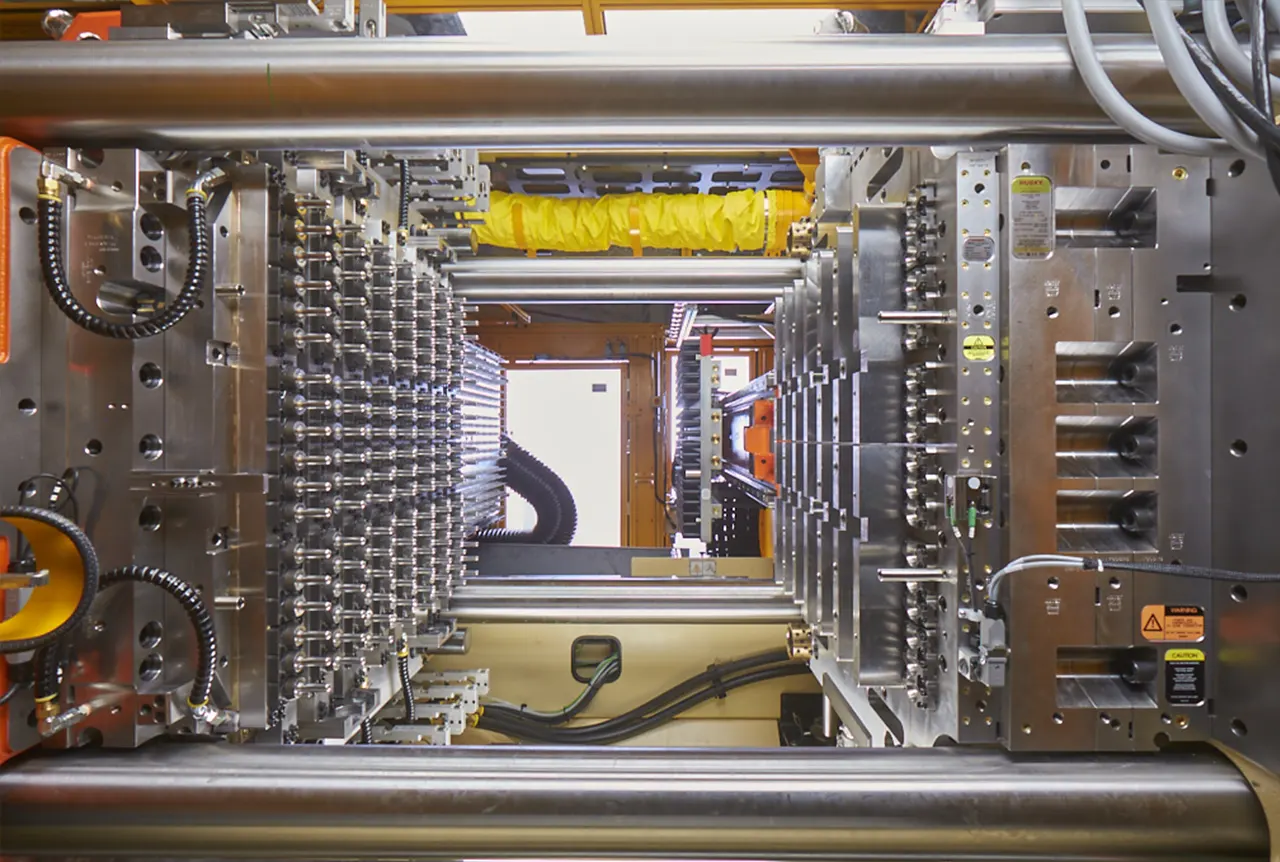

Advanced rPET Processing Technology

HyPET®6e optimizes processing of lightweight bottle preforms using up to 100% recycled PET material without compromising quality or productivity. Key features include:

- Integrated drying solution for accurate material blending and contaminant removal

- High-throughput screw design optimized for superior rPET melt quality

- Uniform melt delivery for consistent lightweight applications

- Real-time inspection system with closed-loop color correction