HyPERSYNC™ is Husky’s next-generation injection molding system—delivering unmatched performance, energy efficiency, and reliability for thinwall food packaging, specialty closures, medical, and personal care applications. From industry-leading cycle times to advanced mold protection and intuitive controls, HyPERSYNC™ redefines what's possible in high-performance packaging production.

See HyPERSYNC™ in Action

Watch how HyPERSYNC™ delivers breakthrough performance for high-speed packaging applications, from synchronized precision to energy-saving innovation.

A New Standard in Packaging Technology

Built on Husky’s industry-leading expertise, HyPERSYNC™ sets a new benchmark in packaging molding. Available from 225 to 600 metric tons with a broad selection of injection units, HyPERSYNC™ offers:

- Synchronized mold and machine processes for ultra-fast cycles

- Advanced Melt flow control for consistent quality with minimal scrap

- High-pressure injection units for fast fill rates and superior throughput

- Stack mold and wide tie-bar support for high-cavitation, heavy molds

- Multi-Layer compatibility for new functionality and design flexibility

Energy Efficiency Without Compromise

HyPERSYNC™ integrates industry-leading energy-saving technologies for reduced operating costs without sacrificing performance:

- Electric Mold Stroke (ELMS) yields high acceleration rates for fast clamp movements

- Regenerative Clamp Stroke recycles breaking energy back to the power grid

- Speed Variable Pump (SVP) supplies hydraulic power on demand

- Up to 40% energy savings over previous-generation systems

Precision and Reliability with Every Cycle

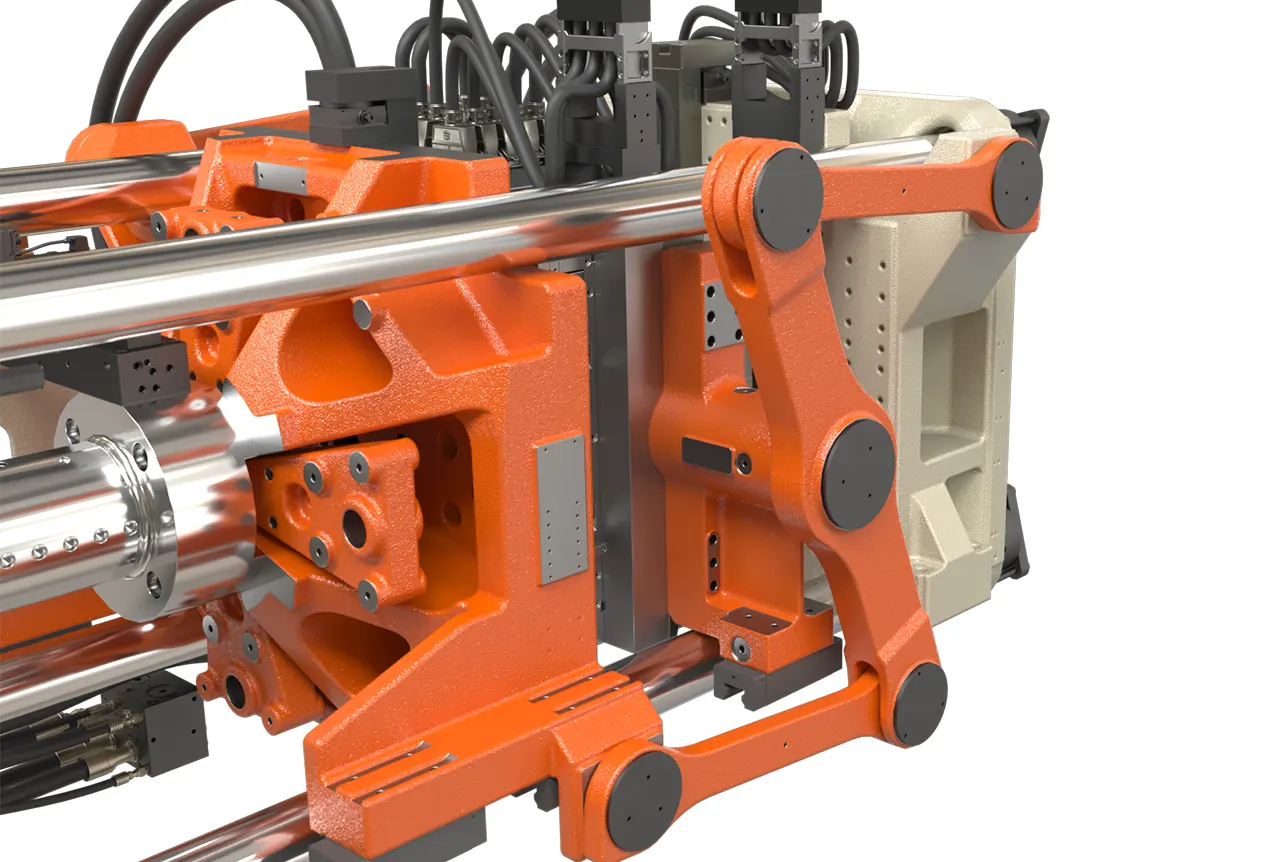

HyPERSYNC™ features Husky’s advanced three-platen clamping unit with Reflex™ platen technology, designed to deliver exceptional accuracy, part consistency, and mold longevity:

- Part weight consistency within 0.1% tolerance

- Superior tonnage distribution for high-quality output with reduced clamping force

- Reduced mold wear for extended tool life

- Precision platen positioning within ~50 microns—about the thickness of an IML label

Advanced Controls for Simpler Operation

Husky's Polaris® enables powerful system-level control at your fingertips:

- 19-inch touchscreen HMI with intuitive controls

- Rapid access to critical process parameters from the main page

- Advantage+Elite™ real-time proactive, predictive, and transparent monitoring tracking over 70 unique performance insights for increased system uptime and production security

How One Producer Cut Energy Use by 35%

A major dairy and deli food brand turned to HyPERSYNC™ to boost productivity and reduce energy costs — without compromising quality. With consistent, accurate IML placement, faster cycles, and less scrap, the results speak for themselves:

- 35% reduction in energy consumption

- Decreased scrap rate

- $30,000 in annual savings

- Longer mold life and better ROI

Contact Us About HyPERSYNC™ High-Performance Packaging Injection Molding Systems

What to consider when choosing your next injection molding machine for food and consumer packaging

Manufacturers and brands are rethinking their injection molding needs to meet consumer and sustainability demands. Download our guide to learn key considerations for choosing an injection molding system tailored to your food and consumer packaging production.