Optimizing Your Existing Molding Operation for Sustainability Without Starting Over

You don't have to rebuild your facility to build a more sustainable operation. For manufacturers processing recycled PET (rPET), the fastest path to meeting sustainability targets often starts with the injection molding systems you are already running.

Strategic upgrades to key components can transform existing equipment to handle up to 100% recycled content, all while reducing material waste, energy use, and cycle times.

In this article, we take a look at four proven steps you can take to modernize your operation for sustainable production, delivering real ROI without starting from scratch.

Step 1: Evaluate Your Current System

The first step toward sustainable production is understanding where your current equipment struggles with recycled content. Most legacy systems weren’t designed for rPET’s unique challenges, but knowing where the gaps lie helps you prioritize investments and avoid costly mistakes.

Focus your assessment on these critical areas:

- Drying system performance: Check if your dryers can maintain the precise temperature control and low moisture levels (below 40 ppm) required for rPET. Older desiccant dryers, especially those more than 10 years old, often need frequent maintenance of molecular sieves and oil condensers, leading to costly downtime.

- Hot runner compatibility: Evaluate whether your hot runners can handle rPET’s variability without flow inconsistencies or part weight variations. Systems designed for virgin materials can often struggle with recycled content, which can increase scrap rates.

- Maintenance frequency: Track how often you’re cleaning molds due to the dust and debris that can build from running recycled materials. If manual cleaning takes two to six hours and is frequent, it can become impractical at higher recycled content percentages.

- Inspection capabilities: Confirm that your quality control systems can detect common rPET defects such as black specks, haziness, bubbles, and color variations not typically found in virgin materials.

A comprehensive evaluation like this reveals which upgrades will have the most impact on your operation. Husky’s experts can also assess your system readiness to help you identify opportunities that deliver the strongest return.

Step 2: Identify Strategic Upgrade Opportunities

Once you’ve identified the gaps in your system, it’s time to focus on upgrades that deliver maximum impact with minimal disruption. The most successful modernization projects address multiple challenges while maintaining production continuity.

Consider these high-impact upgrades:

Vacuum drying technology: Modern vacuum dryers handle high rPET percentages without the oil condensers and desiccants that complicate traditional systems. Husky’s vacuum dryer technology, for example, uses a four-stage continuous drying process with precise temperature control (100°C to 170°C) that prevents thermal degradation while delivering:

- 24% reduction in energy consumption compared to conventional systems

- 75% faster resin changeovers (from eight hours down to two)

- 50% lower maintenance costs over 10 years

Self-cleaning mold technology: High rPET content can cause dust buildup and cleaning interruptions. Self-cleaning mold technology uses controlled flash to automatically remove dust from vents in a single machine cycle, eliminating downtime while maintaining part quality.

Advanced hot runners: Modern hot runner systems like Husky's Ultra Helix™ and UltraSync™ technologies ensure consistent melt delivery and precise valve control. These systems maintain tighter tolerances and consistent part weight distribution, essential when processing variable recycled materials.

Step 3: Upgrade Controls for Smarter Sustainability

Even older equipment can benefit from smarter control systems. Adding monitoring software, smart sensors, and adaptive control modules lets you manage rPET’s variability without replacing your entire control infrastructure.

Focus on these control enhancements:

- Adaptive process modules: Add-on systems automatically adjust to material variations, maintaining consistent part quality despite batch-to-batch differences in recycled content. These intelligent controls monitor key parameters in real time and make micro-adjustments as needed.

- Real-time monitoring systems: Retrofit equipment with sensors and software that detect and correct process variations in real-time as they occur. For example, closed-loop color correction modules can identify and adjust for color shifts in recycled content without operator intervention.

- Sustainability tracking software: Data collection systems capture and report critical metrics, such as energy usage per unit, scrap rates, recycled content percentages, and carbon footprint.

- Predictive maintenance platforms: These systems monitor machine health over time to detect early warning signs of wear or failure. Husky’s Advantage+Elite™ platform, for example, tracks subtle changes in system variables and alerts your teams before they affect production or cause costly downtime.

Step 4: Support Long-Term Gains with Auxiliary Optimization

Don’t overlook the equipment that surrounds your molding machine. Auxiliary systems directly affect both energy consumption and part quality when processing recycled materials.

Upgrading these supporting systems can deliver quick wins with minimal investment:

- Material handling: Install gravimetric blenders with integrated controls to maintain consistent material blend ratios.

- Cooling precision: Add temperature control modules to prevent thermal degradation of heat-sensitive recycled materials.

- Automated part handling: Implement robotic or automated removal systems to reduce part damage and enable consistent quality inspection, especially when running higher recycled content.

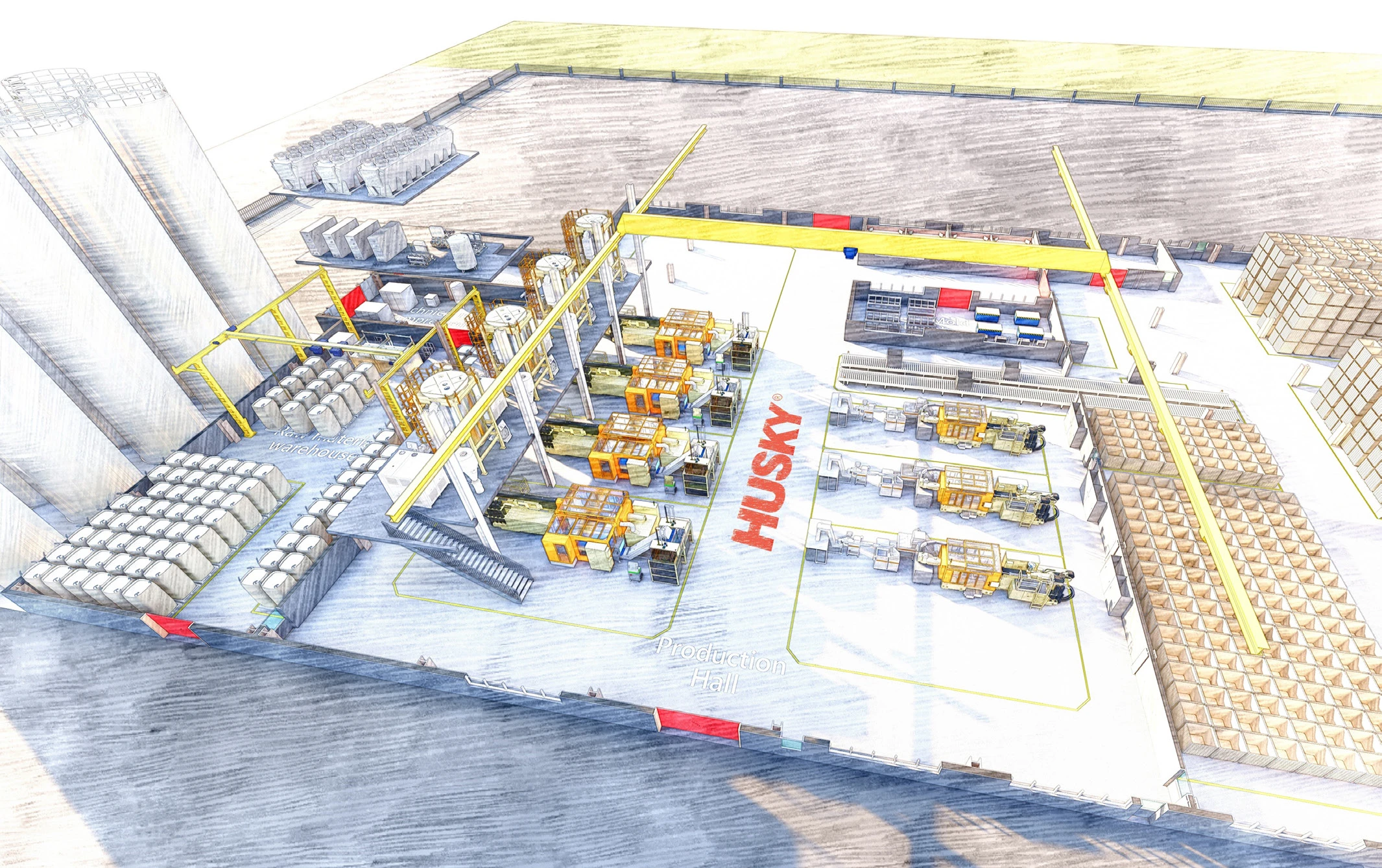

Husky’s complete, integrated system approach ensures all downstream and auxiliary equipment work together for efficient, consistent, sustainable output. This integrated method optimizes the entire production process, delivering superior overall performance with recycled materials.

Application Spotlight: Sustainable Preform Production in the UAE

Mai Dubai, one of the UAE's premier bottled water brands, partnered with Husky to enhance sustainability while expanding production capacity. Using a Husky HyPET®HPP5e system with 128-cavity mold, the company achieved:

- A production capacity of 80,000 preforms per hour

- 100% solar-powered factory operations

- Lightweighted bottles reducing resin consumption

- Real-time monitoring with Advantage+Elite™ for optimal rPET processing readiness

Get Started Today

Strategic upgrades to your existing systems can transform your rPET processing capabilities while protecting your current investments.

Contact Husky today to book an assessment and identify the upgrades that will deliver the strongest ROI for your operation.