ENABLING A MONO-MATERIAL (PET) PACKAGE

Husky’s PET closures offer a sustainable alternative to traditional HDPE closures. Molded from bottle grade PET resin, these closures further enable the circular economy for beverage packaging. These designs deliver environmental, safety and performance benefits for consumers, converters, and brand owners.

CONTACT NOW

BENEFITS:

Husky’s approach to PET closure production is novel and offers the highest level of consumer safety and line performance possible. The primary benefits associated with the SecuRE+ approach include:

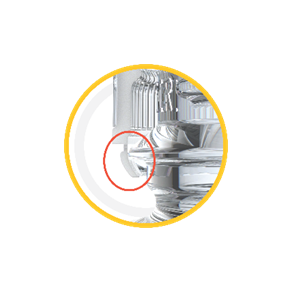

NOVEL TAMPER EVIDENCE:

Our patented approach to tamper evidence provides an unmatched level of security. This provides peace of mind for both the brand and consumer.

STRESS-FREE APPLICATION:

Our design eliminates the need for integrated cams on the tamper evident band. A clearance fit allows the Tamper Evident Band to pass over the pilfer proof like a sleeve. This approach does not introduce any stress on the bridges and results in improved capping performance (lower reject rates).

DUST-FREE MANUFACTURING APPROACH:

As the void between the bridges is created during the molding process, a post-mold slitting approach is not required. Plastic particles (dust) can be created during the scoring operation. All of this is avoided with our designs.

DESIGN FREEDOM:

Complex geometries are possible with our tooling technology. Intuitive tethered designs are possible using our patented tethered designs.

LIGHTWEIGHTING OPPORTUNITIES:

Despite having a higher mass density than HDPE, the more rigid nature of PET unlocks further lightweighting opportunities at the dispensing system level.

BARRIER PERFORMANCE

The molecular structure of the PET molecule provides improved barrier performance vs HDPE. This can extend shelf life for Oxygen sensitive and carbonated beverages.

HIGHER rPET YIELD

Depending upon the application type, the closure can represent upwards of 15% of the total package weight. An all-PET beverage package provides a meaningful improvement in the rPET bale yield.

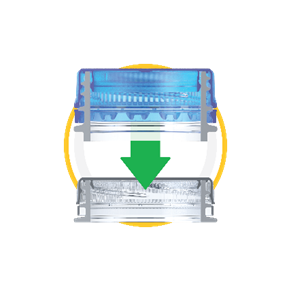

COMPATIBILITY

All of our PET closure designs are 100% compatible with existing CETIE standard neck finishes. No modifications to the necks are required. Just plug and play.