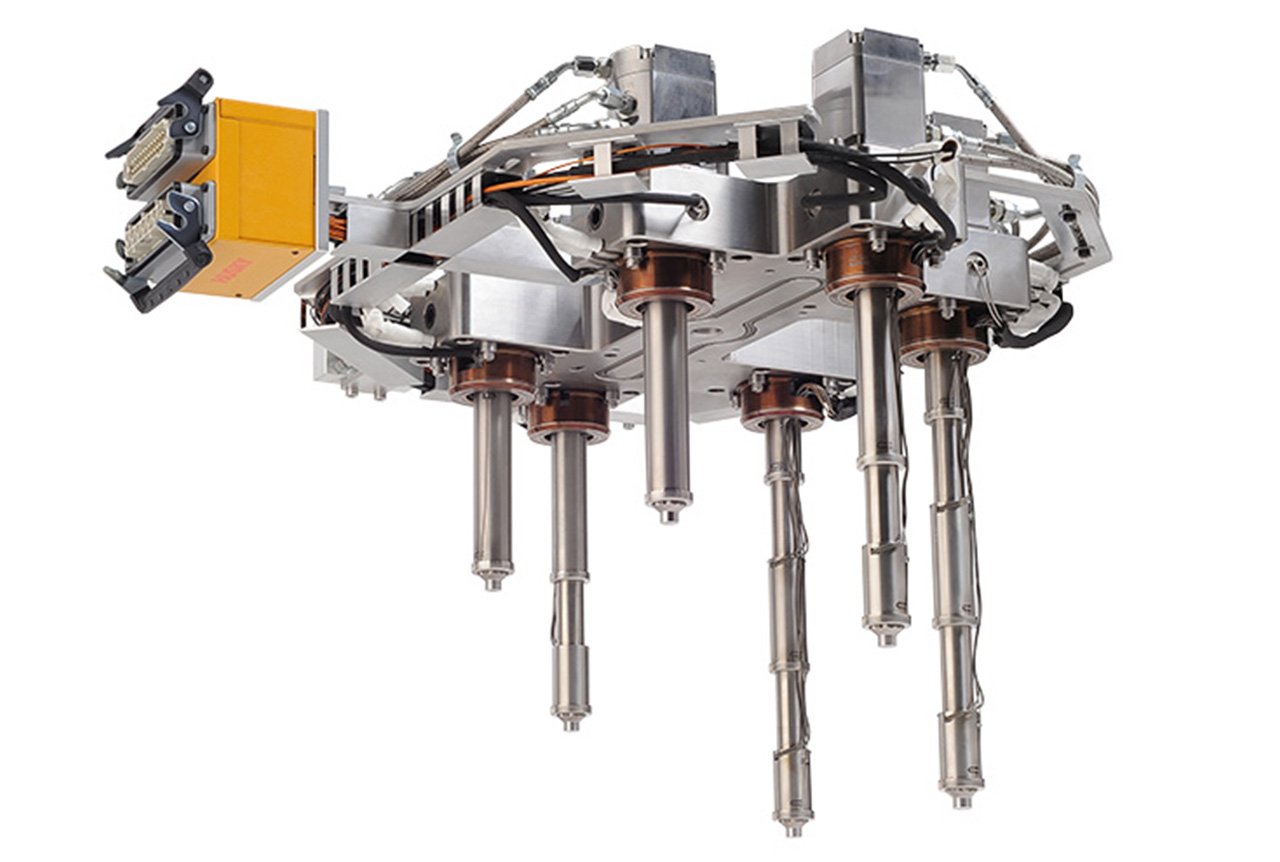

Complete Hot Runner System Configurations

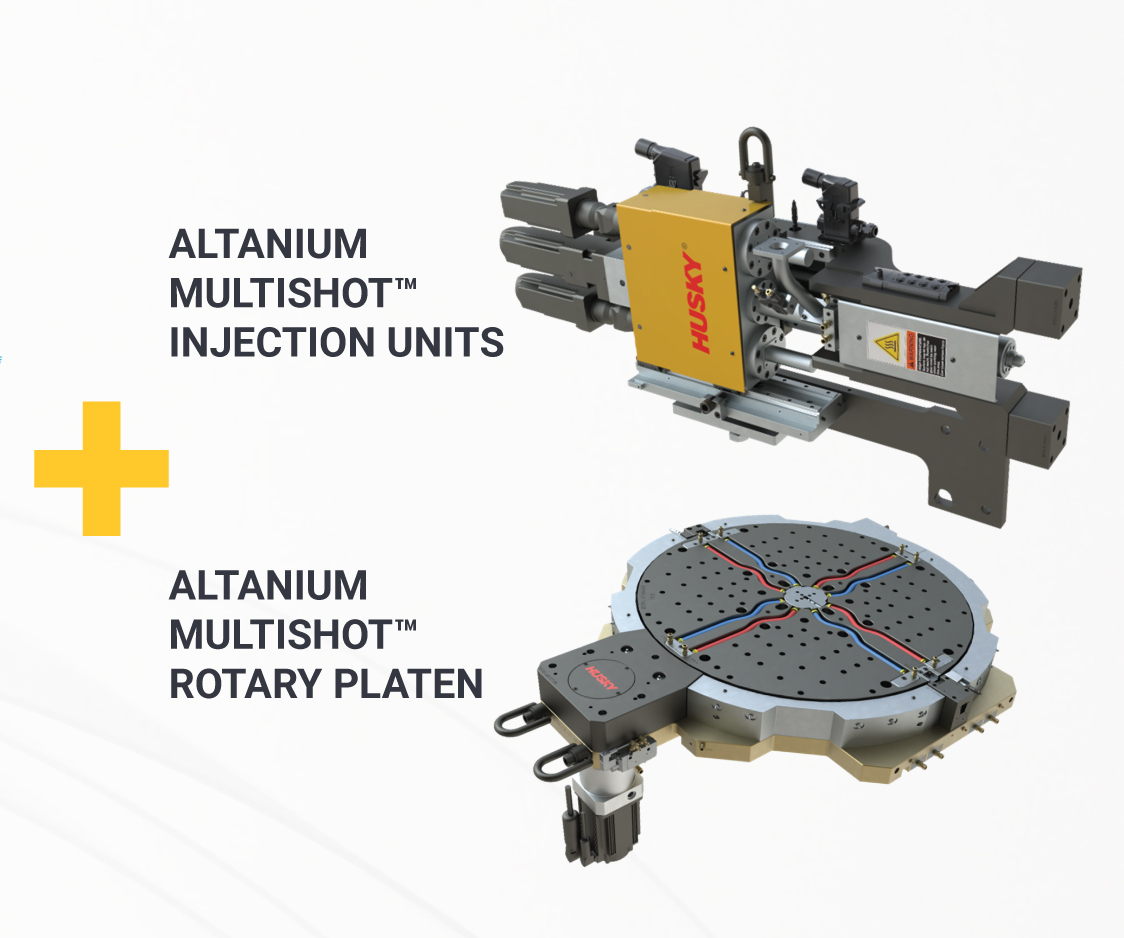

Husky delivers hot runner solutions for every molding challenge, from simple single-level systems to complex multi-material applications. Our comprehensive range includes:

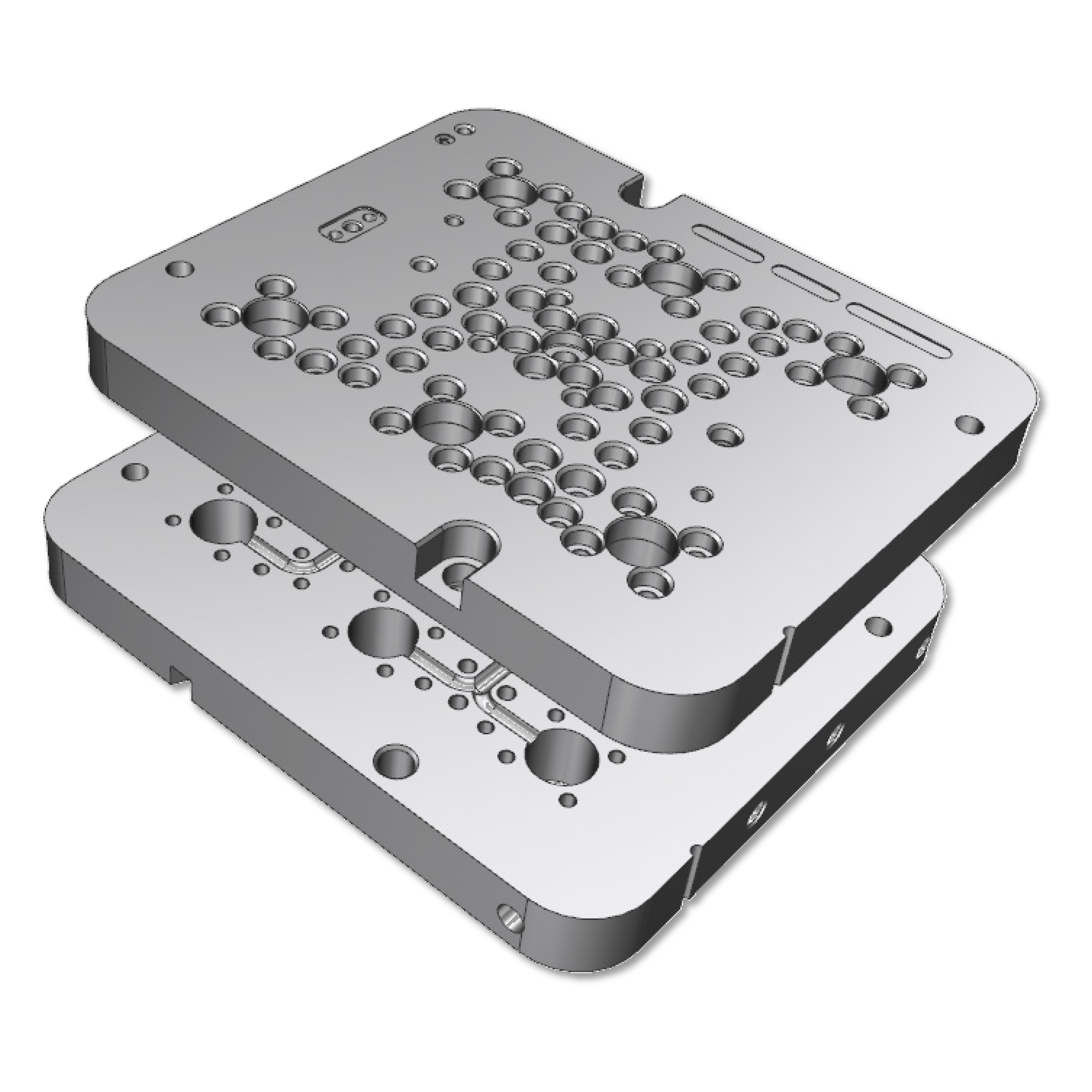

- High-cavitation systems (24–128+ drops): Maximum productivity with balanced flow and fast color changes

- Stack configurations: Double or triple output without increasing machine footprint

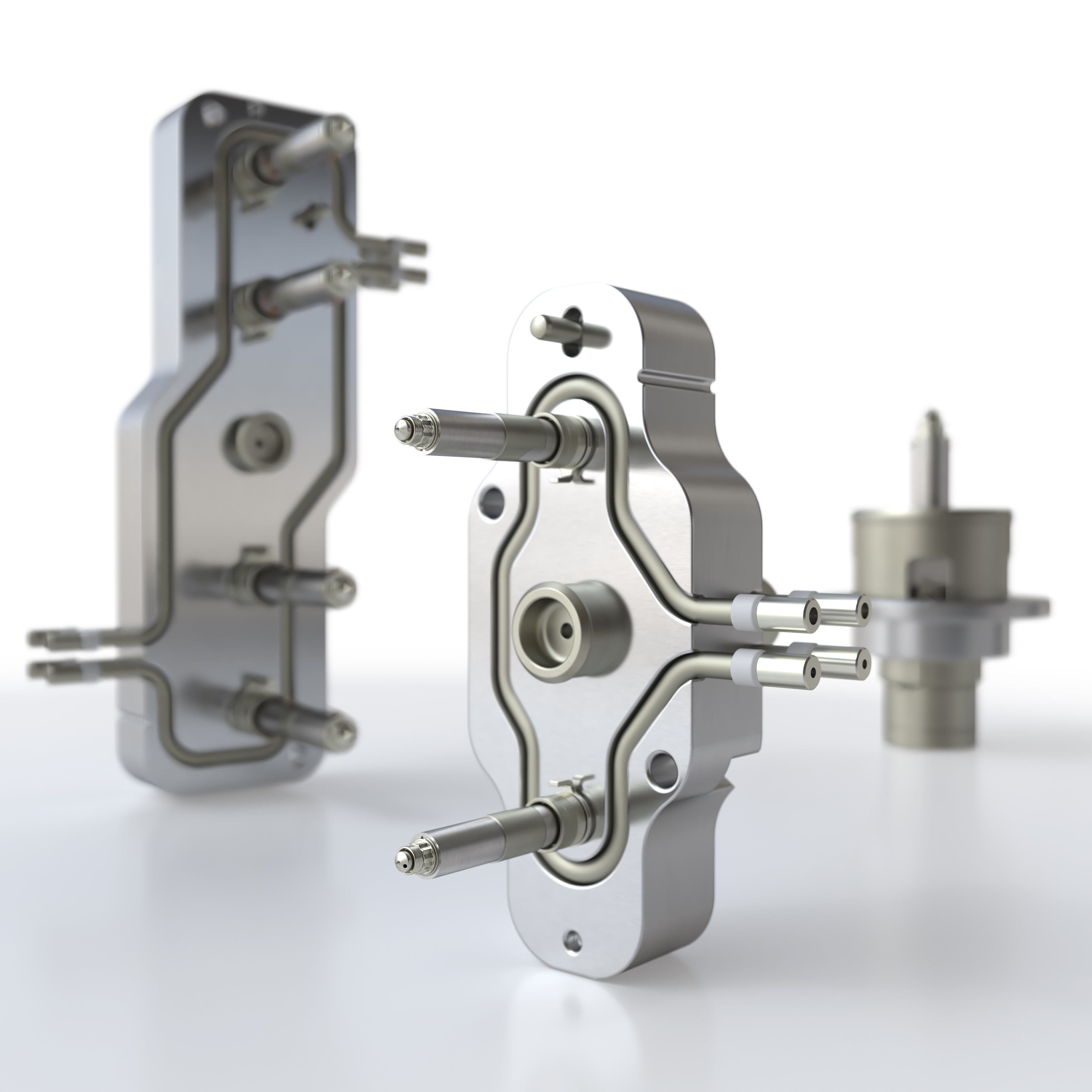

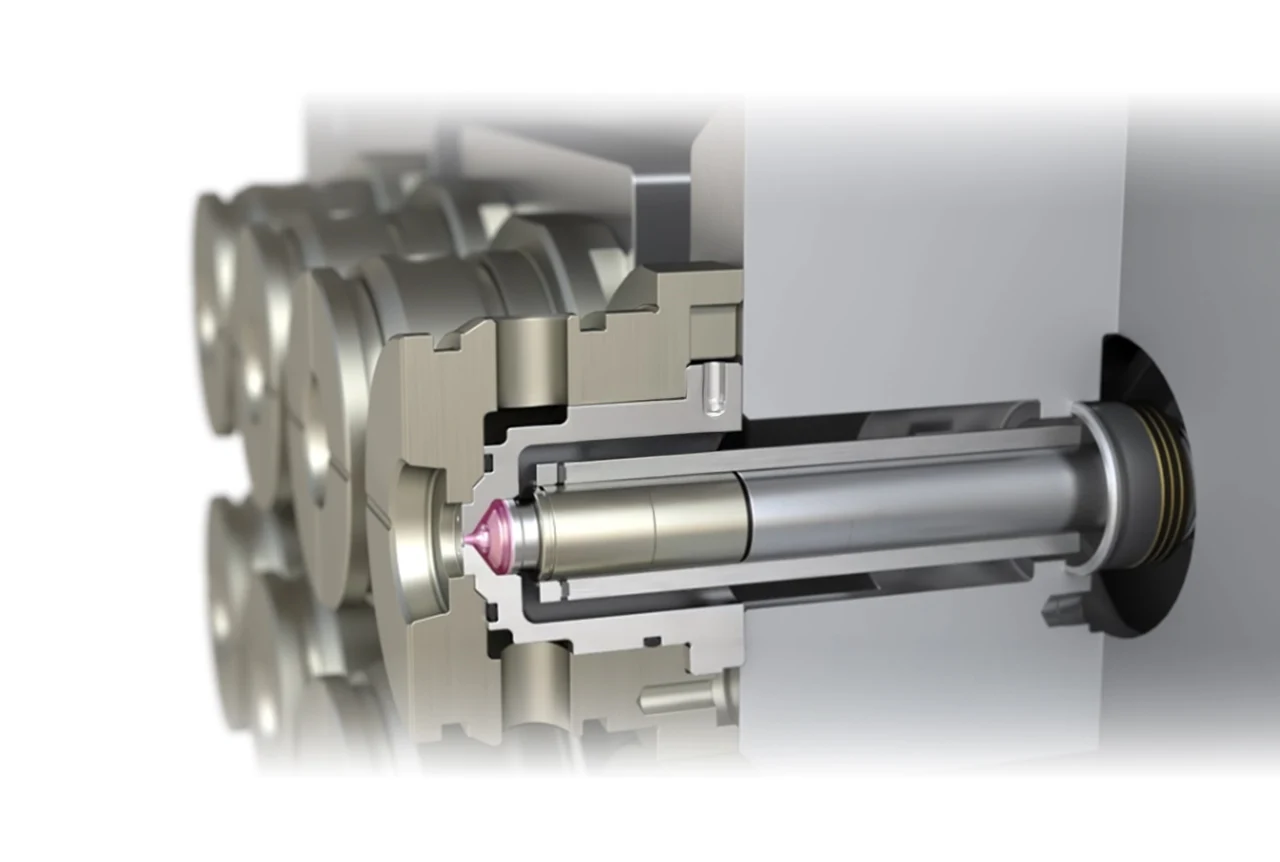

- Multi-material & multi-color: 2+2 to 64+64 valve gates for complex part designs

- Nonsymmetrical & family molds: Custom-engineered systems with flow simulation optimization

- Split-sprue technology: Prevents drool and stringing for cleaner molding areas