Optimize your Molding Operation with New Vacuum Dryer Technology

The global market for recycled PET (rPET) is projected to grow from $12 billion in 2024 to over $21 billion by 2031, driven by shifting consumer preferences, sustainability goals, and regulatory mandates. But as demand increases, many processors are finding their aging desiccant dryers can’t keep up.

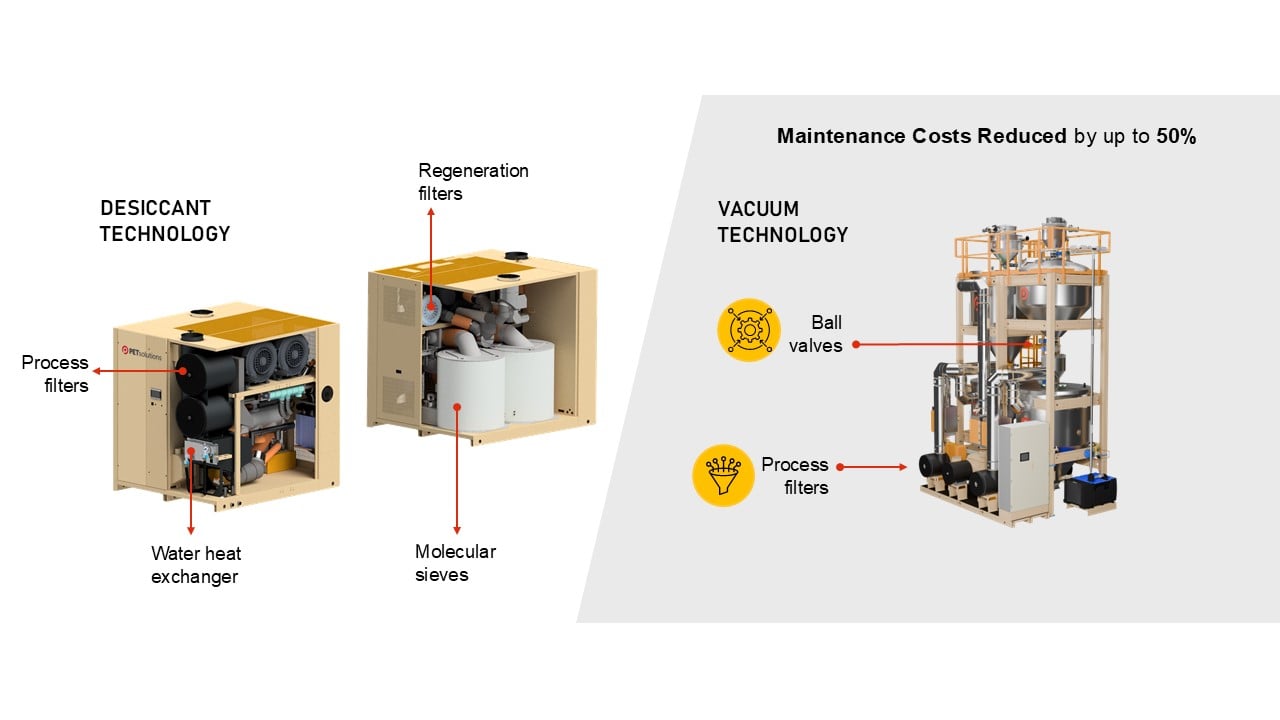

Traditional systems, especially those 10 to 25 years old, struggle with frequent maintenance, inefficient energy use, and limited process control, particularly when handling rPET. These older dryers often require replacement of molecular sieves, heat exchangers, and filters. In some cases, a high-maintenance oil condenser is needed to manage condensable contaminants, adding further complexity and cost.

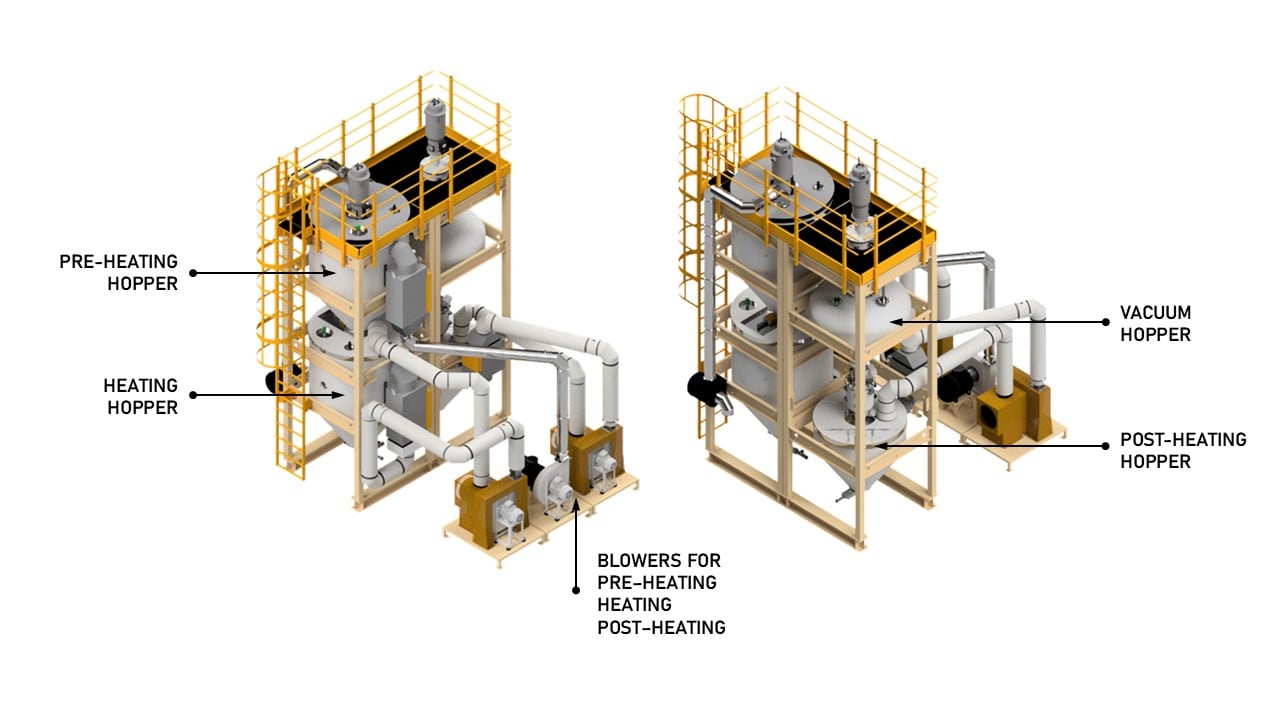

Husky’s Vacuum Dryer technology offers a smarter, more efficient alternative. With a desiccant-free, water-free design and a four-stage continuous drying process, the Vacuum Dryer enables precise control, superior material protection, and higher uptime.

Here are five ways vacuum dryer technology can transform your PET processing operation:

1. Energy Efficiency, Designed for rPET Processing

Drying rPET with traditional systems can be energy-intensive, especially when equipped with an oil condenser. A traditional desiccant dryer equipped with an Oil Condenser can typically require an additional 30 Wh/kg (chilled water requirement and reheating of process air). Because the Vacuum Drying system does not require the use of an Oil Condenser, it consumes up to 33% less energy when processing rPET.

This efficiency advantage is especially critical for rPET processing, where traditional systems demand higher energy consumption to maintain proper drying conditions. By optimizing the drying process and removing energy-intensive components, Husky’s Vacuum Dryer technology not only reduces costs, but also ensures optimal material processing conditions.

2. Lower Maintenance Requirements, Increased Uptime and Cost Savings

Older desiccant dryers come with frequent servicing needs, from filter changes to component replacements. For facilities managing multiple lines, these costs add up.

Husky’s Vacuum Dryer technology cuts maintenance costs by up to 50% by eliminating the need for key maintenance items such as:

- Molecular sieve

- Water heat exchangers

- Regeneration filters

Removing these maintenance components enhances system uptime while reducing labor and spare part costs.

In addition, because its backed by Husky’s integrated Advantage+Elite™ support, the Vacuum Dryer also provides remote performance monitoring, helping producers stay ahead of issues to optimize uptime.

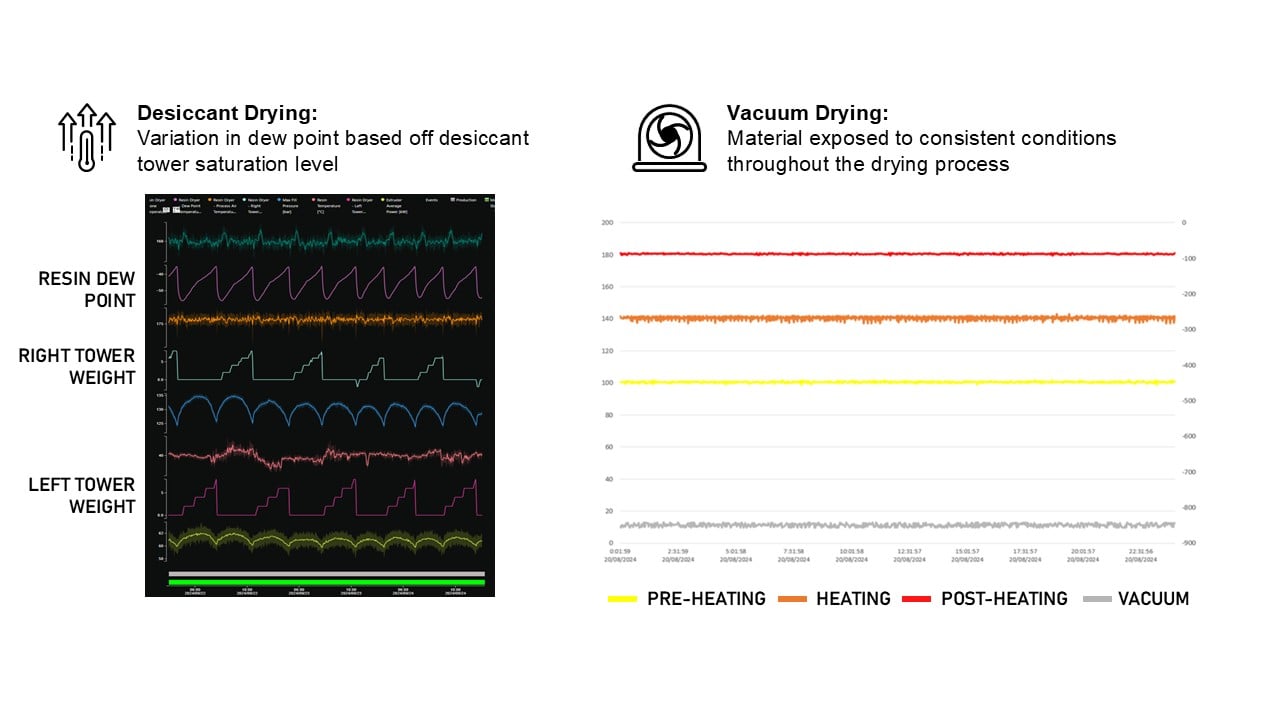

3. Processing Consistency, Predictable Results with Unpredictable Material

Consistency is a critical topic when it comes to processing of any material, but is especially important when processing rPET because the material is starting the process with higher variation. The ability to control the moisture level with a consistent process results in improved performance, reduced defects, less scrap, and an overall higher quality product. The Vacuum dryer is able to hold a relatively uniform vacuum pressure level as its means for reducing moisture. In comparison, desiccant based technology can see fluctuations in air dew point levels as desiccant towers become saturated and when desiccant towers switch from a saturated tower to a dry tower.

4. Enhanced rPET Processing Capability, Lower Scrap Rate

Processing rPET introduces unique challenges, particularly around thermal degradation. This can occur at temperatures above 160°C, leading to yellowing, acetaldehyde (AA) generation, and condensable contaminant generation.

Desiccant drying systems designed for processing virgin PET operate at a single process air temperature, limiting the system to lower heat levels or necessitating accepting quality issues related to thermal degradation.

Husky’s Vacuum Dryer technology uses a precise four-stage process to prevent degradation and protect rPET quality, which involves:

- Pre-heating at 110°C

- Closed loop heating to 130-140°C

- Vacuum drying phase, reducing moisture to <40 ppm

- Final heating optimized at 160-180°C for molding readiness

Crucially, this process dryer keeps rPET below 160°C for 75% of the drying cycle, helping preserve color, AA levels, and mechanical properties, while accommodating any mix up to 100% rPET content.

5. Fast Resin Changeovers, Increased Uptime

For converters running multiple materials, resin changeovers are a major productivity drain. Traditional desiccant dryers can take eight hours to complete a changeover, including hopper emptying, resin loading, and reheating.

Husky’s Vacuum Dryer technology cuts this process down to just two hours, thanks to its four-stage process.

For operations performing one changeover per week, that’s a potential 312 additional production hours per year. And because this technology is fully integrated with Husky’s injection molding systems, changeovers are synchronized with mold changes, improving overall system efficiency.

Ready to Upgrade?

If your current drying system is holding you back from your sustainability, energy efficiency, or uptime targets, it might be time for an upgrade.

Husky’s Vacuum Dryer technology enables:

- Significant energy savings for rPET processing, drastically reducing operational costs

- Rapid resin changeovers, cutting downtime from 8 hours to just 2, for a quick return on investment

- Up to 50% lower maintenance costs over a decade, translating to substantial long-term savings and fewer disruptions

- Enhanced flexibility with modular designs that seamlessly integrate into any factory layout, optimizing space and production flow

- Superior rPET quality through precise temperature control, preventing degradation and preserving material integrity

- Complete system integration with proactive, remote monitoring via Advantage+Elite™ for maximized uptime and peace of mind

Get Started With Husky

Get in touch to discuss your PET processing needs and learn how Husky's advanced vacuum dryer technology can enhance your rPET operations, reduce costs, and improve efficiency.