Husky is leading sustainability without compromise at KShow 2025

BOLTON, ON – Husky Technologies™, a global leader in injection molding technology and solutions, is showcasing its latest innovations in packaging, hot runner, and medical molding solutions at KShow 2025, held in Düsseldorf, Germany from October 8-15. Located in Hall 13, Booth A61, Husky is demonstrating how the company is redefining molding so brands and producers can achieve sustainability and performance, quality, and security, without compromise.

“Husky’s return to KShow represents more than a product launch, it’s a defining moment in our journey to reshape the future of manufacturing,” said Bradley Selleck, Husky’s CEO. “The technologies we’re unveiling are the result of relentless innovation, deep collaboration, and a belief that sustainability and performance, quality and security are not opposing forces, but powerful allies. At Husky, we’re not just engineering systems, we’re empowering the industry to produce responsibly, think boldly, and lead with purpose.”

Next-Generation Packaging Molding Platform

Having a more than 70-year history in pioneering packaging molding innovation, Husky has maintained a strong track record of developing solutions that lead the industry in productivity, automation, and streamlined production.

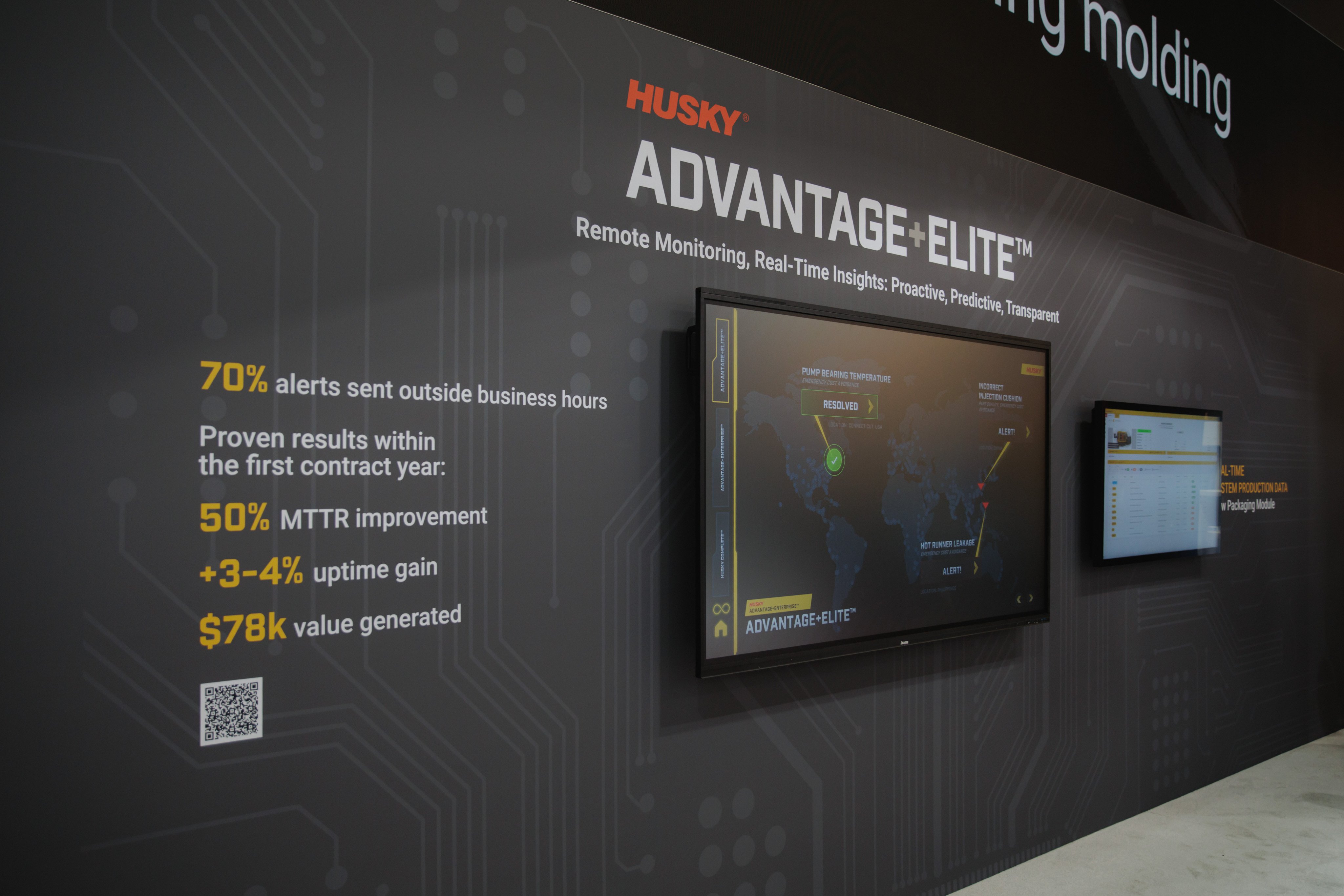

At KShow, Husky is unveiling the next evolution in high-performance packaging molding with a complete digital platform. Featuring a bold new design, enhanced system architecture, and fully integrated hot runner and mold controller technologies, the platform is further strengthened by Husky’s proven Advantage+Elite™ remote monitoring service. Already securing more than 1,500 Husky PET and Closure systems worldwide, Advantage+Elite™ is now offered for the new Packaging molding platform. By tracking more than 70 new packaging performance parameters in real time, the service delivers proactive insights that help maximize efficiency, reliability, and overall performance management.

Running daily throughout the full course of the show will be a new high performance HyperSync™ system, producing a recycled polypropylene lightweight thinwall dairy cup application with in-mold label and running a 3.8 second cycle time. The system incorporates a fully integrated melt delivery system, robot, and auxiliaries, including an 8-cavity mold and side-entry robot from Muller, Husky Ultra Helix hot runner, Husky Delta5™ Mold Controller with DataWave 2.0 technology, and PET Solutions upstream auxiliaries.

Also being introduced is Husky’s next generation Hylectric®6 platform featuring increased energy efficiency, enhanced user experience, improved performance via reduced non-process time, and optimized feeds screws yielding boosted throughput and recovery capabilities. The new system is connected to Advantage+Elite™ 24/7 remote monitoring to alert customers with actionable insights.

“Unveiling this long-anticipated evolution of our packaging molding solution is a proud moment for Husky,” said Robert Domodossola, Husky’s President of Systems and Tooling. “This launch is more than an upgrade, it’s a bold step into the future of high-performance injection molding. It reflects decades of engineering excellence, brought together in a unified ecosystem that is digital, integrated, and purposefully designed to support a more sustainable industry.”

Introducing Altanium MultiShot™ Technology

Also being introduced for the first time at KShow is the company’s new Altanium MultiShot™ technology that redefines multi-material molding. This fully integrated solution combines advanced secondary injection units along with rotary platen technology to transform conventional single-barrel machines into high-efficiency, multi-material production cells.

Designed to enhance manufacturing flexibility, throughput, and performance, Altanium MultiShot™ empowers producers to expand molding capabilities while maintaining precision and efficiency. The launch reinforces Husky’s commitment to delivering scalable, future-ready systems that support evolving market demands and sustainable production goals.

Powering Performance Across Industries – From Food and Consumer Packaging to Medical Applications

Husky is also demonstrating its latest advancements in hot runner and controller technologies, engineered not just for melt flow, but to expand possibilities across packaging, medical, personal, and home care markets. These innovations deliver next-level reliability, high-volume durability, and intelligent control to enable producers to achieve greater efficiency, precision, and profitability.

On display is the new Ultra Helix 2.0 Valve Gate system, offering unmatched robustness, and cycle consistency to maximize uptime and productivity, as well as the next generation Ultra SideGate™ 2.0, which now supports up to 8-tip configurations in a compact mold design, enabling millions of cycles of repeatable performance.

New product announcements continue with the groundbreaking launch of the company’s new Altanium™ controller platform including Neo6™, Delta6™, and Matrix6™. These fully redesigned controllers redefine precision and profitability with faster startups, superior resin protection, and optimized energy use.

In the medical market, Husky’s industry-leading solutions support the production of critical devices – from pre-filled syringes, pen injectors, and auto-injectors, to pipette tips and petri dishes. Through integration with Schöttli’s™ proprietary gating technologies, Husky is expanding capabilities across parenteral, diagnostics, and laboratory applications, where precision is a critical necessity and reliability is non-negotiable.

About Husky

Since 1953, Husky Technologies™ has been pioneering technologies that enable the delivery of essential needs to the global community with industry-leading expertise and service. A global leader, Husky is powered by teams of exceptional people in more than 40 locations with valued customers who operate in over 140 countries. By focusing on sustainably sourced feedstocks, material reuse and the exclusive use of medical-grade polymers, Husky continues to be committed to enabling the circular economy now and into the future.

– 30 –

For more information:

Media Relations

Husky Injection Molding Systems

media@husky.ca