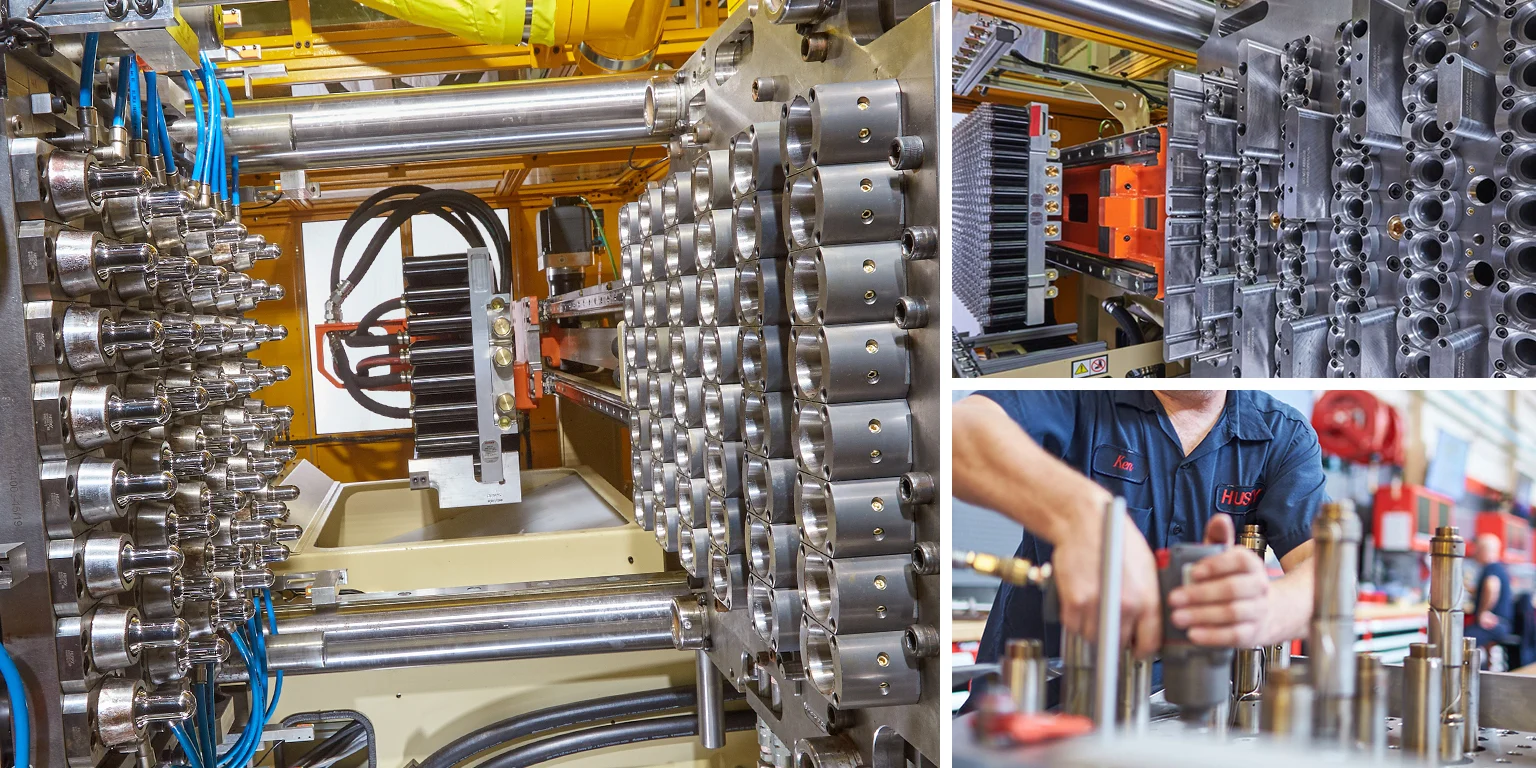

PET Preform Mold Technology

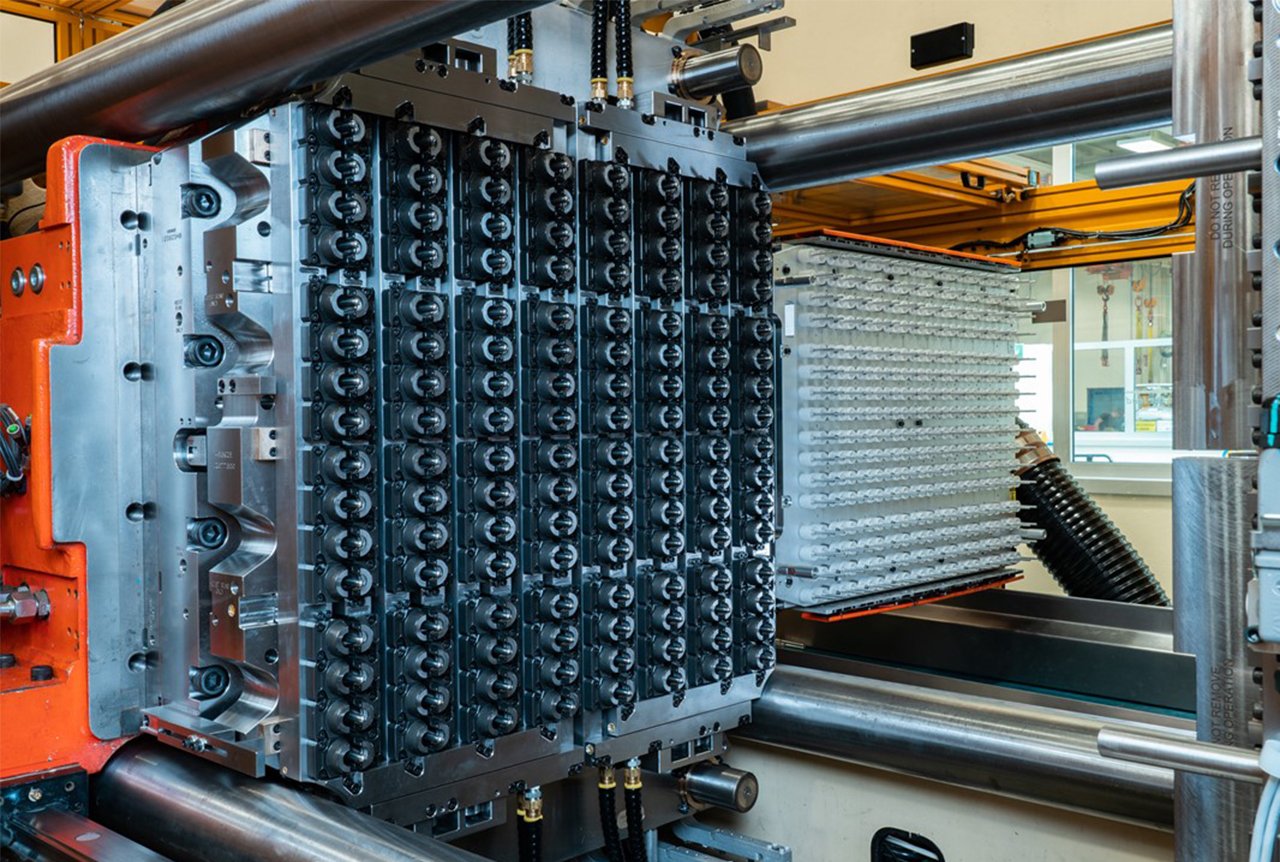

Husky PET preform injection molds deliver exceptional performance for beverage and packaging applications. From 2 to 200 cavities, our advanced multi-cavity mold designs provide:

- Self-cleaning technology extends maintenance intervals up to 500,000 cycles

- Ultra hot runner systems for superior gate quality and faster color changes

- Mold ID connectivity for mold-to-machine communication that optimizes processing parameters automatically

- Advanced rPET processing, handling up to 100% recycled content without compromising quality

- Flexible configurations with industry-lowest dimensional variability

Our comprehensive tooling support includes advanced mold conversions for weight-saving designs and express refurbishment services that reduce downtime from weeks to hours.