Husky Enables Sustainability without Compromise at Drinktec 2025

BOLTON, ON – Husky Technologies™, a pioneering technology provider enabling the delivery of essential needs to the global community, is showcasing its latest breakthroughs in sustainable beverage packaging production at Drinktec 2025, taking place in Munich, Germany, from September 15 -19. Located in Hall C5, Booth 421, Husky is presenting new technologies, solutions, and services that enable the circular economy and redefine what it means to produce sustainable beverage packaging without compromise.

"At Husky, we believe sustainability should never mean compromise,” said Bradley Selleck, Husky’s CEO. “The industry has moved beyond the old trade-offs between recyclability, performance, quality, or speed. PET is uniquely positioned as the most circular packaging material and at Drinktec 2025, we're proud to showcase how Husky is enabling beverage packaging producers to build a truly circular future while continuing to grow their businesses.”

Global Debut of Next-Generation HyPET®6e 200-Cavity Platform

One of the show’s highlights is the world premiere of Husky’s next-generation HyPET®6e platform, featuring a 200-cavity system engineered to deliver unmatched productivity. This system introduces new advanced vacuum drying technology that takes rPET processing to the next level by delivering superior energy efficiency, precise control, material protection, and higher uptime.

HyPET®6e enables producers to process higher levels of rPET with confidence, while maintaining consistent part quality and lowering overall part costs. By combining throughput with sustainability, the system is designed to meet today’s demand for circular packaging and high performance.

Introducing HyCAP™ SecuRE+: One Material, One Package

At the show Husky is also launching HyCAP™ Secure+, a breakthrough closure forming technology that enables bottles and closures to be made entirely of PET, creating a fully circular, mono-material package.

Key benefits include:

- Enhanced consumer security through a novel tamper-evident design

- Improved capping performance for greater line efficiency

- Compatibility with complex/tethered closure geometries

- Compatibility with industry standard CETIE neck finishes

- Lightweighting opportunities at the dispensing system level for cost savings and sustainability gains

When paired with Husky’s advanced closure development expertise, HyCAP SecuRE+™ empowers producers to align with global circular economy goals while delivering superior package performance.

“The combination of our next-generation HyPET®6e 200-cavity system and new HyCAP™ SecuRE+ closure technology represent game-changing advances for the beverage industry,” said Robert Domodossola, Husky’s President of Systems and Tooling. “With HyPET®6e, producers can achieve unparalleled scale and efficiency while processing higher levels of rPET with confidence and consistency. SecuRE+ complements this by enabling a true complete mono-material PET package, bottle and closure together, delivering new levels of consumer security and recyclability. These innovations redefine what’s possible, proving that sustainability and performance can advance hand in hand.”

Official Launch of Advantage+Enterprise™

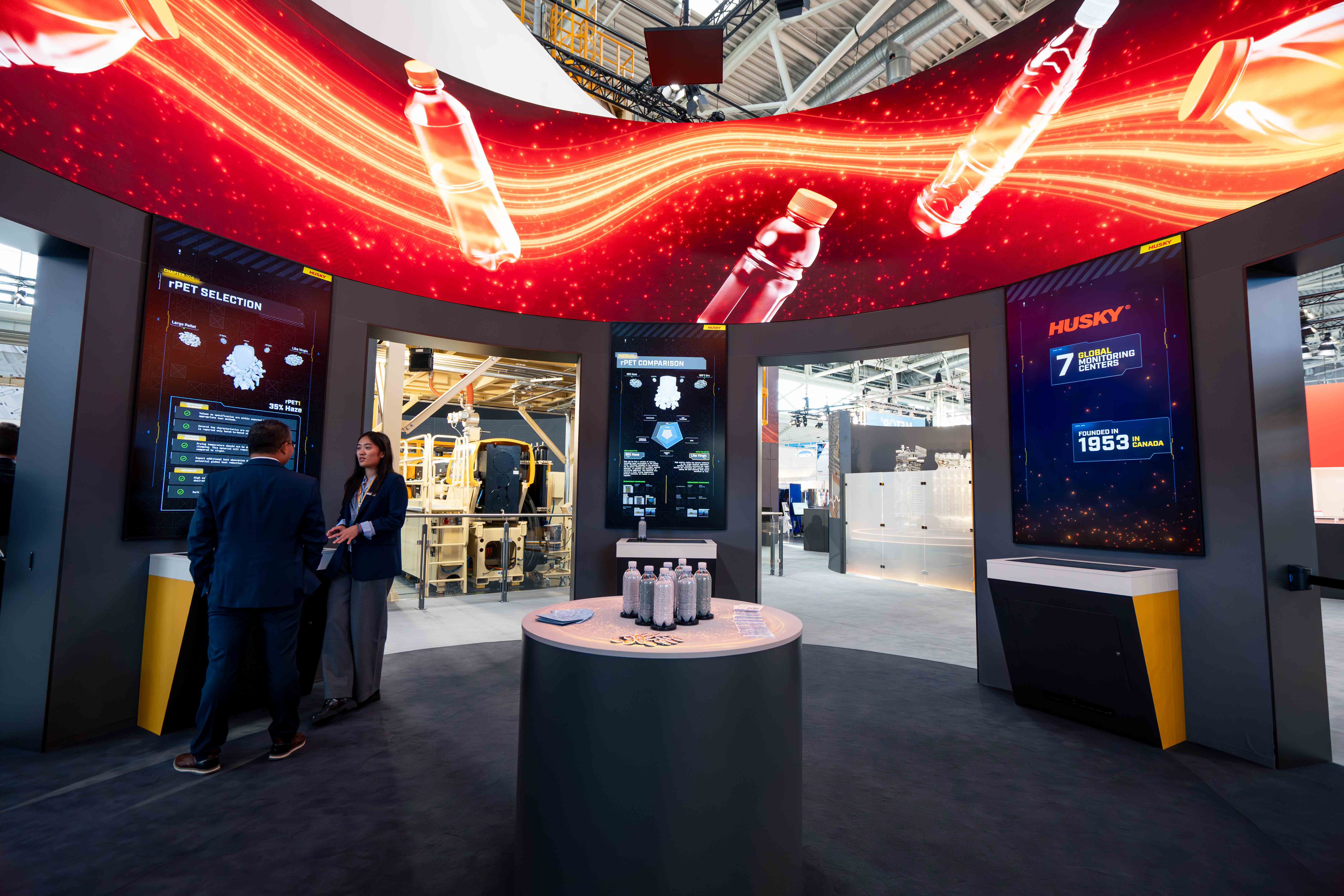

Drinktec 2025 also marks the official launch of Husky’s Advantage+Enterprise™, a new global monitoring solution that builds on the company’s proven Advantage+Elite™ platform.

Since its introduction in 2021, Advantage+Elite™ has been deployed in more than 1,500 customer contracts worldwide, delivering significant improvements in operational effectiveness, performance, and part quality. Husky’s data demonstrates that customers connecting entire factories to Advantage+Elite™ realize even steeper gains. These insights directly informed the development of Advantage+Enterprise™, which expands monitoring to the enterprise level.

The expanded solution offers:

- Enterprise-wide operational visibility across single factories or multi-factory networks

- Improved decision-making for labor allocation, rPET integration, and predictive maintenance

- Resilience and efficiency to help producers manage variability and reduce waste

“Our customers have told us they need more than single system-level predictive monitoring and proactive alerts — they need visibility across entire plants and even multi-factory, multi-country networks,” said Tony Black, Husky’s President of Service. “Advantage+Enterprise™ delivers exactly that, providing manufacturers with powerful enterprise-wide insights through targeted dashboards designed for operations, maintenance, and executive teams. By driving efficiency, quality, performance, and resilience — whether it’s bridging labor gaps, integrating recycled PET, or improving overall equipment effectiveness — this solution empowers producers to make faster, smarter decisions that protect both their bottom line and the planet.”

About Husky

Since 1953, Husky Technologies™ has been pioneering technologies that enable the delivery of essential needs to the global community with industry-leading expertise and service. A global leader, Husky is powered by teams of exceptional people in more than 40 locations with valued customers who operate in over 140 countries. By focusing on sustainably sourced feedstocks, material reuse and the exclusive use of medical-grade polymers, Husky continues to be committed to enabling the circular economy now and into the future.

– 30 –

For more information:

Media Relations

Husky Technologies

media@husky.ca