For temperature, valve gate and servo control, nothing beats Husky’s proven family of Altanium mold controllers. They are Industry 4.0-ready—the most integrated platform in the business, offering single-point operation and control of hot runner temperature, mold servo and valve gate sequencing. They also feature best-in-class diagnostic capabilities and fault-recovery solutions thanks to their H-Series Intelligent Control Cards, which are interchangeable across the entire production line.

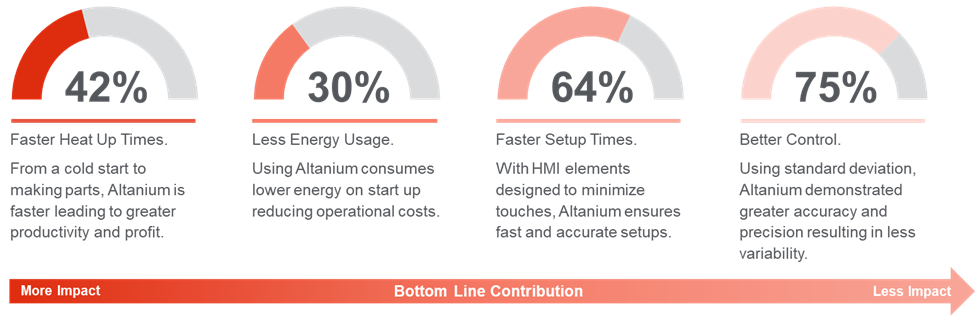

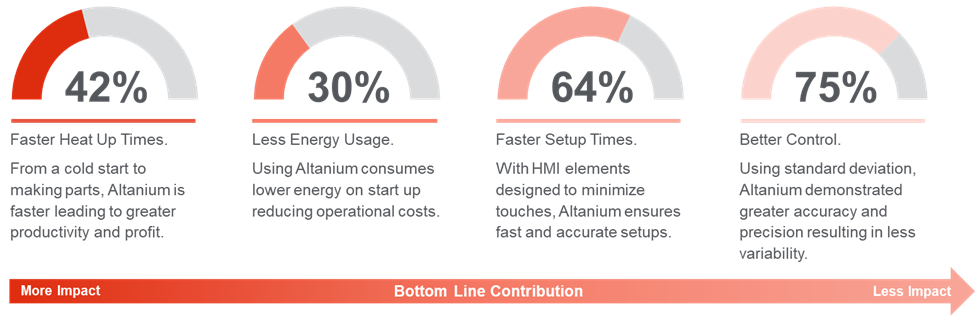

Engineered for superior control and ease of use, all Altanium™ mold controllers now include our all-new proprietary second-generation Active Reasoning Technology (ART 2.0). The ART 2.0 control algorithm enhances our best-in-class hot runner temperature control by incorporating more advanced autotuning and heat-up strategies reducing tuning time, heat-up time, residence time, and energy usage. The result is exceptional out-of-the-box performance, with ART 2.0 providing up to 42% faster heat-up times, while using 30% less energy than existing temperature control solutions.

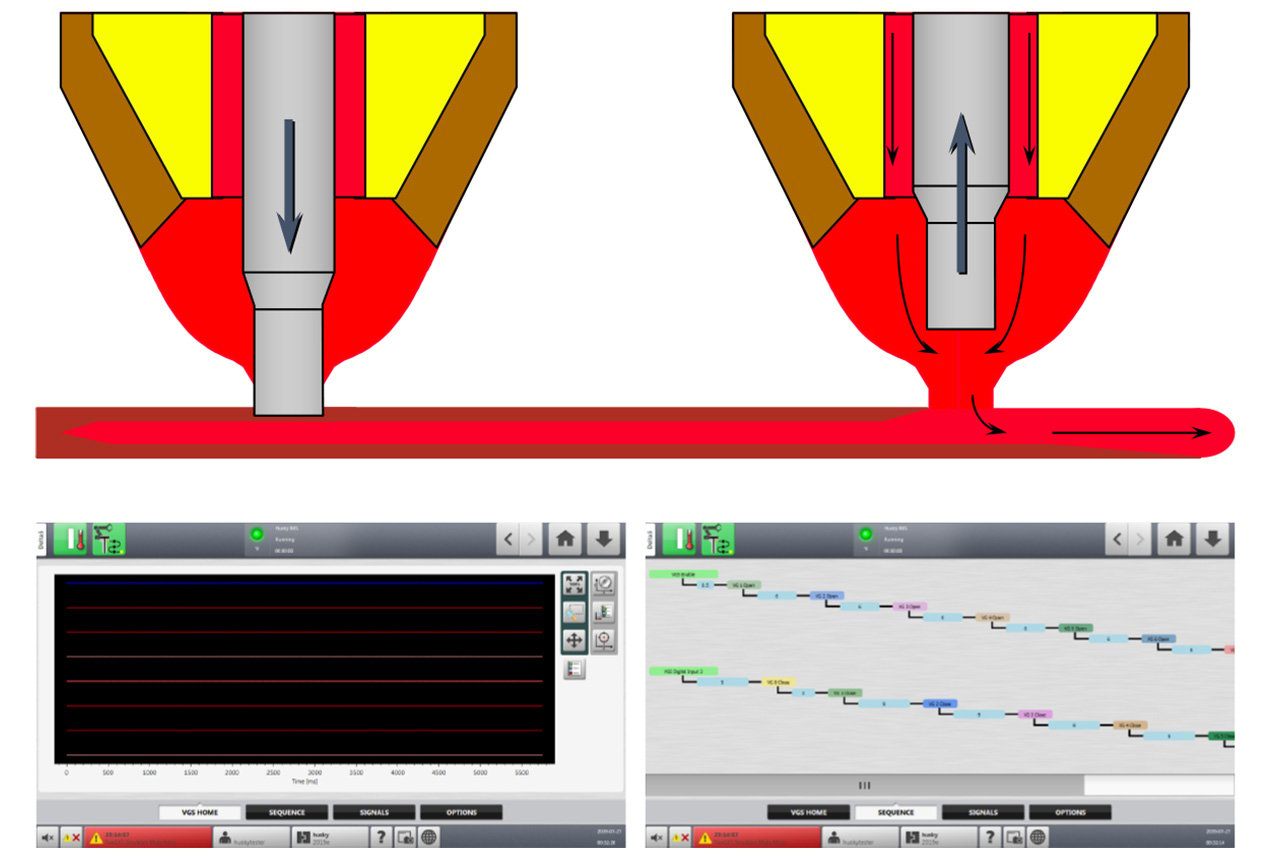

At the heart of ART 2.0 are two unique heating strategies:

- UniStart – Fastest heat-up times, while promoting even thermal expansion of the hot runner

- AltaStart – All of the UniStart advantages with the added benefits of lower energy consumption and reduced residence time in the nozzles

These strategies enable more parts per startup, directly impacting your bottom line. ART 2.0 delivers tighter control and minimizes variability through rapid, smooth power output delivery, fully isolated thermocouple inputs, and industry-leading thermocouple sample rates that ensure the integrity of temperature readings from the mold. This new control technology elevates Altanium to deliver accurate and precise temperature controller, reducing shot-to-shot and cavity-to-cavity variability, resulting in better melt stream management and a more capable molding cell producing higher quality parts.

All Altanium mold controllers are also backed by an industry-best 5-year warranty that includes the operator interface, H-series control cards and mainframe. Just a few of the many reasons Husky is tops among mold temperature controller suppliers.

Altanium mold controllers offer:

- 2 to 255 zones of temperature control

- Second-generation Active Reasoning Technology (ART 2.0)

- Best-in-class troubleshooting and fault recovery

- Multi-language support

- Password- and username-enabled security

Discover which Altanium controller is right for you. Or download our brochure.