Sustainable Savings: 5 Ways Modern PET Molding Systems Reduce Total Production Costs

Beverage manufacturers are under increasing pressure to do more with less, cut costs, shrink emissions, and meet sustainability targets, all while maintaining high output and part quality.

With PET preform molding systems representing a significant capital investment, forward-thinking producers are looking beyond the initial price tag to understand how sustainable molding technologies can dramatically reduce total production costs over time.

In this article, we'll explore advanced technologies like Husky's industry-leading systems and five ways they are enabling manufacturers to reduce production costs.

Energy Optimization: Cutting Costs Through Adaptive Technology

Energy costs represent one of the largest operational expenses for PET preform and bottle manufacturers. With global energy prices trending upward and experiencing significant regional variations, implementing energy-efficient technologies has become a strategic necessity for maintaining predictable manufacturing costs and preserving profit margins.

To address this, leading manufacturers are increasingly turning to Husky's HyPET®6e platform. Designed for maximum efficiency, the system reduces energy consumption compared to previous generations while maintaining or even improving production speeds. At the heart of these savings is Husky's adaptive system pressure technology, which continuously gathers feedback from sensors to deliver precisely the amount of power required for each application without compromising cycle times or part quality.

Even when running 100% recycled PET, the HyPET®6e achieves impressive cycle times, proving that sustainability and performance can go hand in hand.

Beyond the machine itself, proper facility planning can further enhance energy efficiency. Husky’s Advisory Services team works closely with manufacturers to optimize layout, equipment configuration, and supporting systems, creating the most energy-efficient production environment possible.

Strategic Lightweighting: Less Material, More Savings

When multiplied across millions, or even billions, of units, every gram of PET resin saved translates into major cost reductions. For high-volume producers, eliminating just one gram from each preform can yield hundreds of thousands of dollars in annual savings, while also reducing transportation costs and carbon emissions throughout the supply chain.

Husky’s advanced systems enable the production of ultra-lightweight preforms without sacrificing the strength or performance of the final PET bottle. In some cases, this precision engineering has helped clients reduce material usage by up to 20% compared to conventional designs.

Achieving such material reductions without compromising PET bottle integrity requires exceptional process control. Husky’s molding technology ensures consistent wall thickness and optimal material distribution throughout the preform. An optimized melt delivery system enables PET bottle walls that are thin yet strong, delivering high performance with less material.

What sets Husky’s technology apart is the ability to accommodate higher percentages of recycled PET (rPET). By precisely managing the molding process, manufacturers can use more recycled content while still producing lightweight, high-quality bottles that meet today’s market expectations.

APPLICATION SPOTLIGHT

By converting from a PCO 1881 neck finish to Husky's innovative 26/22 CSD GME30.40 solution, a global beverage producer achieved a 1.48-gram reduction per bottle. The cumulative impact was transformative: annual savings of 1,184 metric tons of resin, elimination of 3,011 metric tons of carbon emissions, and approximately $1 million USD in reduced production costs.

Efficient rPET Processing: Turning Recycled Content into Competitive Advantage

As recycled PET (rPET) becomes a cornerstone of innovative sustainable packaging, manufacturers face the challenge of processing this material while maintaining part quality and reducing variability. Husky’s HyPET®6e systems are engineered to handle up to 100% rPET content without sacrificing performance, quality, or speed.

At the core of this capability is an integrated drying and resin preparation solution that enables more accurate blending, removes metal contaminants, and prepares material consistently. This approach helps overcome common rPET processing challenges, including:

- Inconsistent moisture content affecting process stability

- Fluctuating intrinsic viscosity impacting part strength

- Contaminants leading to defects or equipment wear

- Color variation compromising brand consistency

HyPET®6e’s high-throughput screw design ensures exceptional melt quality, while a built-in, self-adjusting inspection system enables closed-loop color correction, automatically detecting and adjusting for input variability in real time.

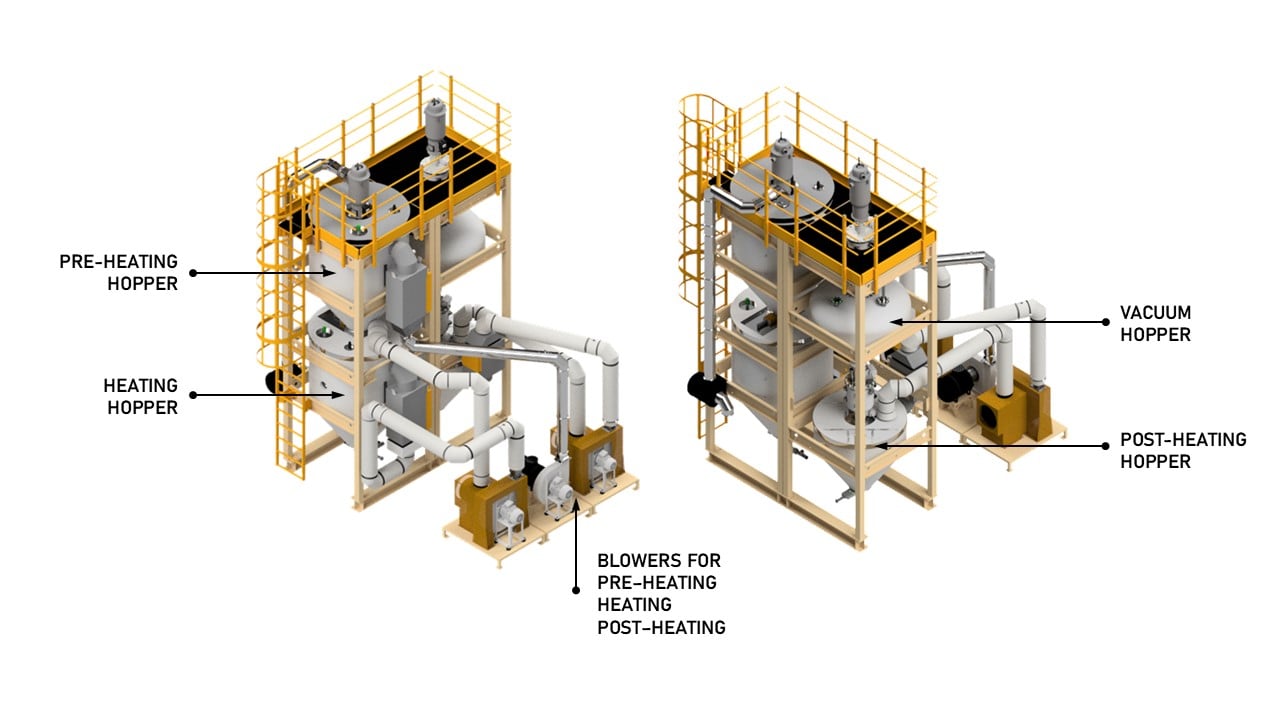

In addition, Husky’s new Vacuum Dryer technology enables consistent drying of virgin and rPET, higher uptime with quick resin changeovers, and lower maintenance costs with the removal of key maintenance components. Because Vacuum Dryer technology does not require the use of an oil condenser, it consumes up to 33% less energy when processing rPET. By optimizing the drying process and removing energy-intensive components, Vacuum Dryer technology not only reduces costs but also enables optimal material processing conditions for higher-quality parts.

These capabilities not only help manufacturers meet stricter recycled content regulations but also strengthen brand appeal in a market where consumers increasingly value sustainable packaging.

Intelligent Quality Control: Converting Defect Prevention into Profit

Husky's integrated quality control technologies prevent defects in PET preform production, transforming quality assurance from a necessary expense into a source of cost savings and a potential driver of profitability.

Key innovations include uniform preform cooling, which boosts part quality without slowing cycle times, and intelligent mold systems that continuously monitor performance, detecting and resolving potential issues before defects occur.

The impact is measurable: a 1% reduction in scrap at a plant producing 1 million preforms daily can save more than $100,000 USD annually in material costs alone. But the benefits go even further:

- Greater operational efficiency through fewer interruptions

- Increased labor productivity by reducing sorting and rework

- Lower downstream costs from smoother blow molding and filling

- Stronger customer satisfaction due to fewer complaints and returns

Predictive Maintenance: Maximizing Production Uptime and ROI

When every hour of downtime cuts into profitability, minimizing production interruptions is essential. Husky's built-in maintenance features keep production running smoothly and costs under control through innovations like:

- Simplified greasing that can be performed while the machine is running, eliminating stoppages for routine maintenance

- Automated self-cleaning molding technology that clears dust buildup when processing high percentages of rPET, preventing defects and extending time between maintenance cycles

To further minimize downtime, Advantage+Elite™ remote connectivity offers a proactive layer of support. This “we call you” model uses real-time system monitoring to flag and resolve potential issues before they disrupt production, often alerting teams before they’re even aware of a potential problem.

Complementing this predictive service, the Husky COMPLETE™ Portal provides instant access to OEM parts, maintenance guides, videos, and other resources for fast, effective on-site troubleshooting.

Together, these smart maintenance tools typically reduce the total cost of ownership over a system’s lifetime. They also reduce labor costs, extend equipment life, and minimize reliance on specialized service technicians.

Explore Sustainable Production with Husky

Reach out to our team of PET experts to learn how Husky's advanced systems can transform your production. Book an assessment, and we'll evaluate your specific needs, recommend tailored strategies, and help you achieve both cost efficiency and sustainability goals.