Versatile Mid‑Volume PET Preform Production

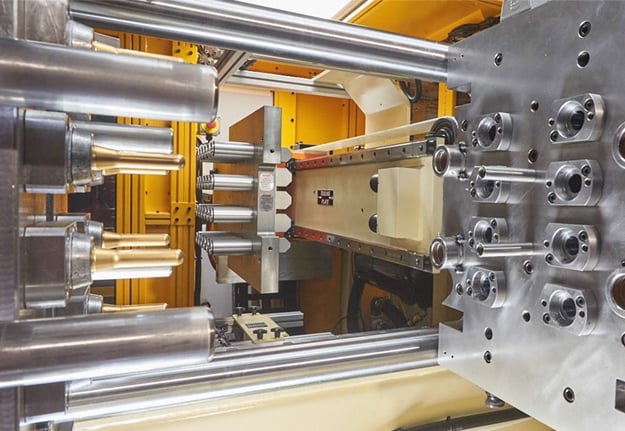

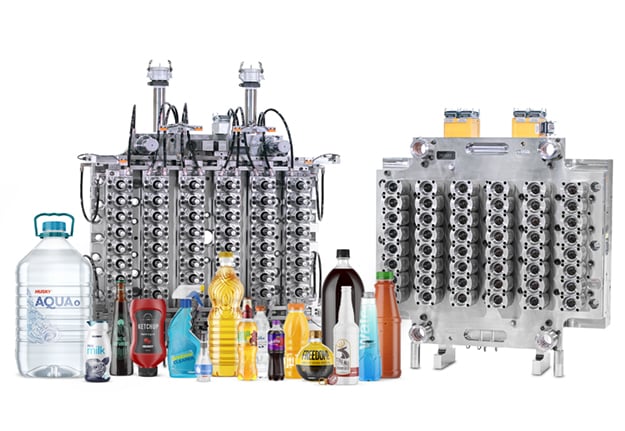

- Wide range of configurations: Choose from multiple RS injection unit sizes and cavitation options to match your production needs for a wide range of output - from 3,000 to 20,000bph, up to 130mm neck finish

- Cost-effective scalability: Lower CAPEX and total cost to produce for incremental capacity or new applications.

- Adaptable for multiple SKUs: Simplify SKU transitions with quick mold changeovers

- Sustainability built-in: Featuring advanced energy management, Engineered for lightweighting and capable of running up to 100% rPET

- Reliable performance: Proven Husky technology ensures consistent preform quality, uptime, and global support for peace of mind.