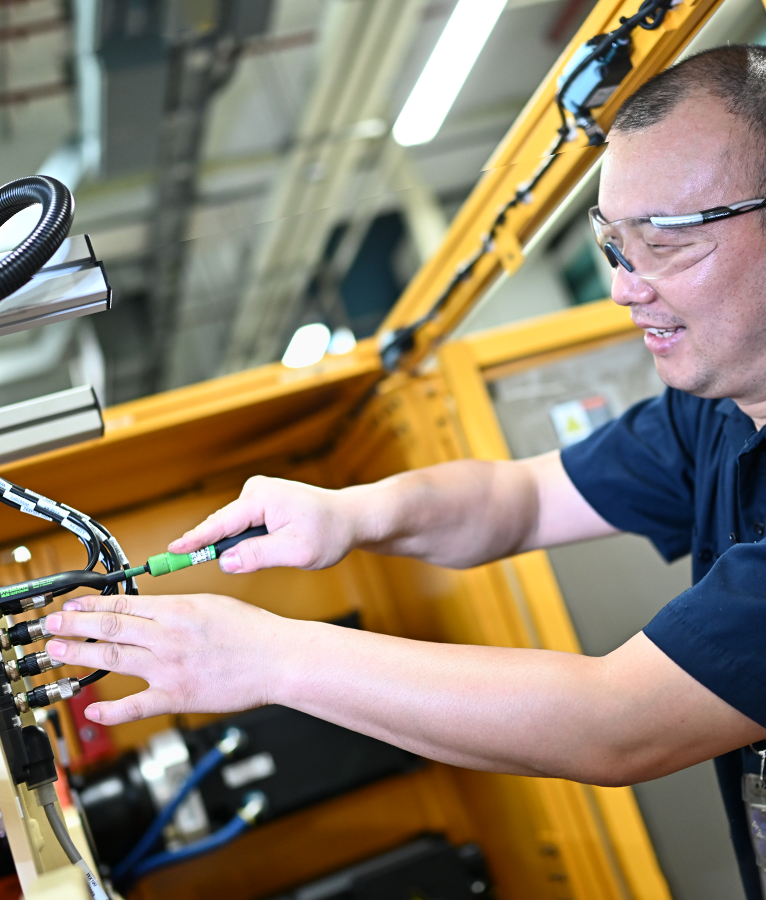

Machine Operation Training

Machine Operation training focuses on the essential skills required to operate Husky injection molding systems safely and consistently. Participants learn how machines are constructed, how key components interact, and how to navigate operator interfaces with confidence.

Courses cover:

-

Machine components and process flow

-

Safety systems and safe operating practices

-

Operator interface navigation

-

Machine setup, startup, and shutdown procedures

-

Manual and automatic operation

-

Basic troubleshooting and defect recognition

Ideal for: Operators, setup technicians, supervisors, and anyone responsible for daily machine operation.