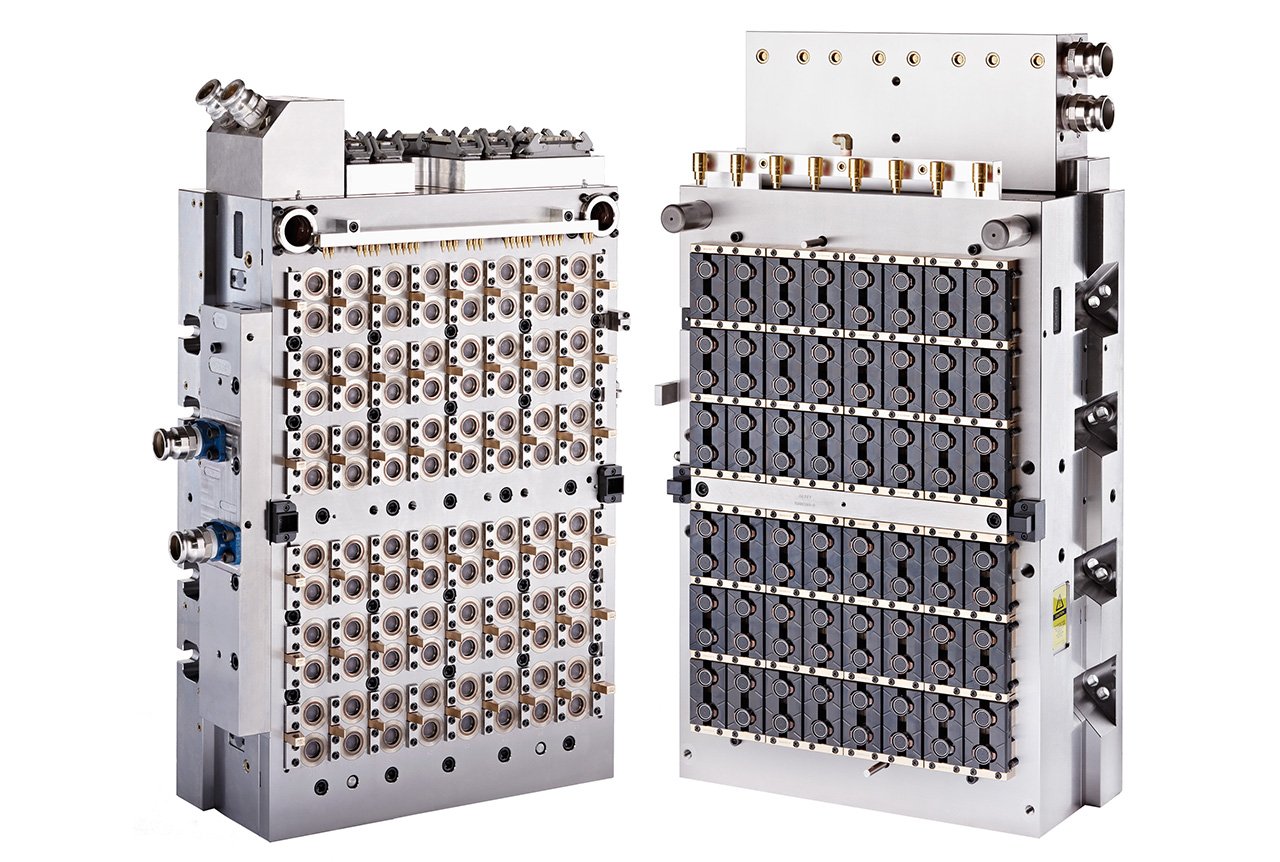

Beverage Closure Molds

For high-speed performance, robustness and quality, nothing outperforms HyCAPTM closure molds. These molds are an integral part of our advanced HyCAPTM4 injection molding system. Innovative features like free motion slides eliminate the need for horn pins and photo eyes, thereby improving cycle performance and avoiding the risk of mold collisions. Rigid plate designs with optimized cooling patterns contribute to a robust mold design that is optimized for speed. Our HT-S6 hot runner tip design improves color change performance and provides optimal gate quality. Mold ID enhanced features like Eject Assist help to simplify setup and optimize cycle time.

Husky beverage closure and tethered closure molds deliver:

- Closures of the highest quality

- Best-in-class manufacturing efficiency

- Best-in-class manufacturing productivity

- Sustainability solutions

- Hygienic safety solutions

Our dynamic portfolio of closure options are compatible with industry standard neck sizes for the water, carbonated soft drink (CSD) and sensitive (JSDT) markets. Our portfolio is available in a wide variety of resin and master-batch combinations to meet OEM levels of performance. To comply with the upcoming European Directive, Husky is developing a portfolio of innovative tethering solutions that prioritize the consumer experience without compromising performance or weight.