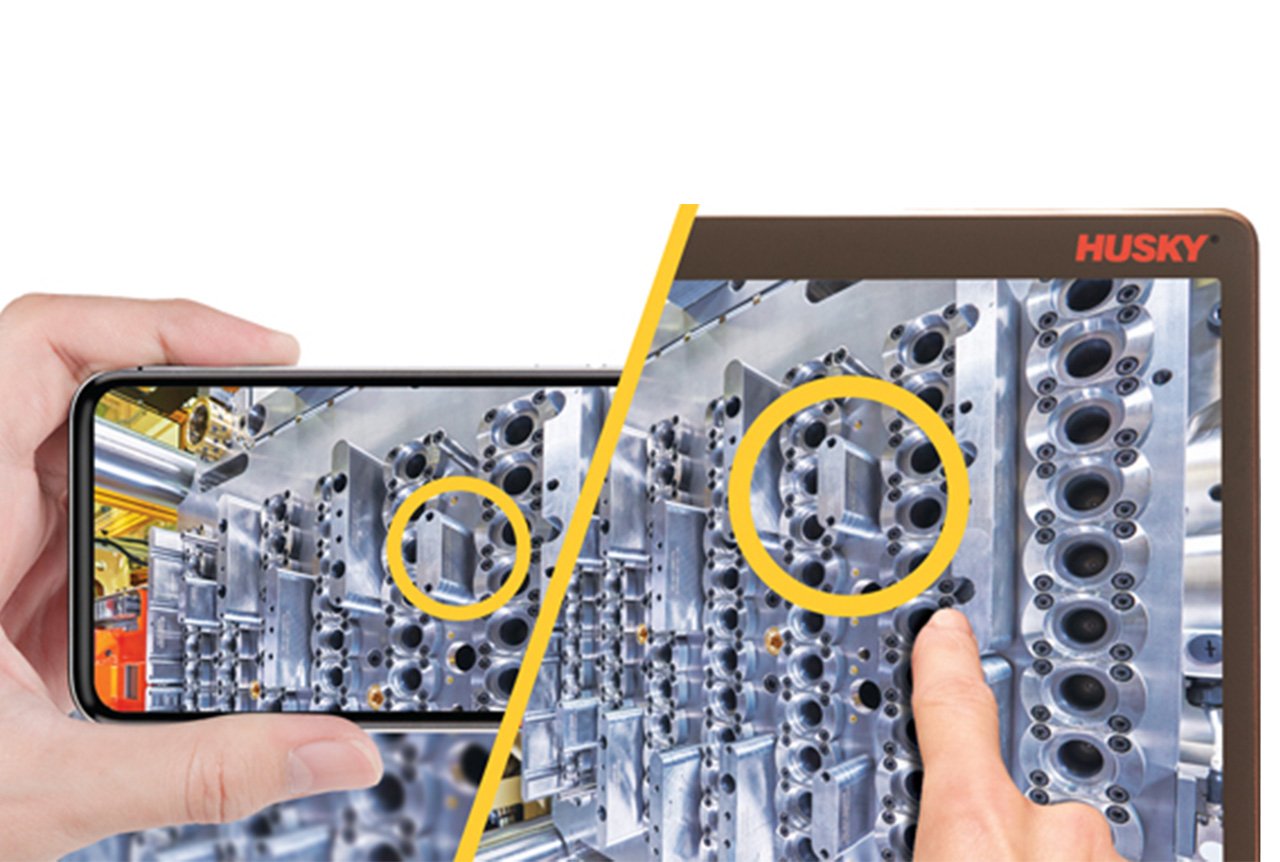

OEM Replacement Parts

Peace of mind comes with all genuine OEM Husky parts. Learn why they’re the best choice to keep your system operating at peak performance, and how they can be ordered faster.

Husky systems, molds and hot runners are legendary for their dependability and low total cost of ownership. Husky’s customer support services, products and service contracts keep your manufacturing operations on schedule by helping you avoid unplanned downtime and expensive repairs. These include genuine OEM spare and replacement parts and upgrade options for machines, robots and auxiliaries, as well as component repair or refurbishment. Plus, real-time process monitoring and preventive maintenance programs, and our Extended ProtectionTM plan. All with the goal of keeping you in greater control of your bottom line.

Husky services protect your investment, keep your costs predictable and help ensure your production lines are always available to deliver at peak capacity. Discover all the pluses Husky’s services provide you.

Peace of mind comes with all genuine OEM Husky parts. Learn why they’re the best choice to keep your system operating at peak performance, and how they can be ordered faster.

Having a Husky service contract in place for your Husky systems ensures against unplanned downtime and costs. Learn about our Advantage+EliteTM, Extended ProtectionTM and Pro-ActTM plans.

Modernize your existing Husky injection molding system. Our upgrade options make it easy to extend the life of your equipment and enhance its productivity.

Improve the performance and productivity of your older legacy Husky system with our advanced Shotscope® 4.0 software. It monitors and analyzes all of your systems’ performance and history.

Husky is here for its customers, prospective customers, partners and communities—whatever you need, whenever you need it. Simply complete our form and we’ll do the rest. You can count on it.